Detailed analysis of Toyota's different hybrid systems: THS, Hybrid MAX, i-FORCE MAX, PHEV, Multi-Stage HEV

Kevin WongSep 16, 2025, 02:36 PM

Kevin WongSep 16, 2025, 02:36 PM

[PCauto] Many people only know about Toyota's THS, but in fact, as the first automaker to mass-produce hybrid vehicles, Toyota also has expertise in other hybrid system technologies.

In addition to the THS used in the Camry and Corolla, Toyota also has models featuring four other hybrid technologies available globally: Hybrid MAX, i-FORCE MAX, PHEV, and Multi-Stage HEV.

THS (Toyota Hybrid System) Power-Split Hybrid System

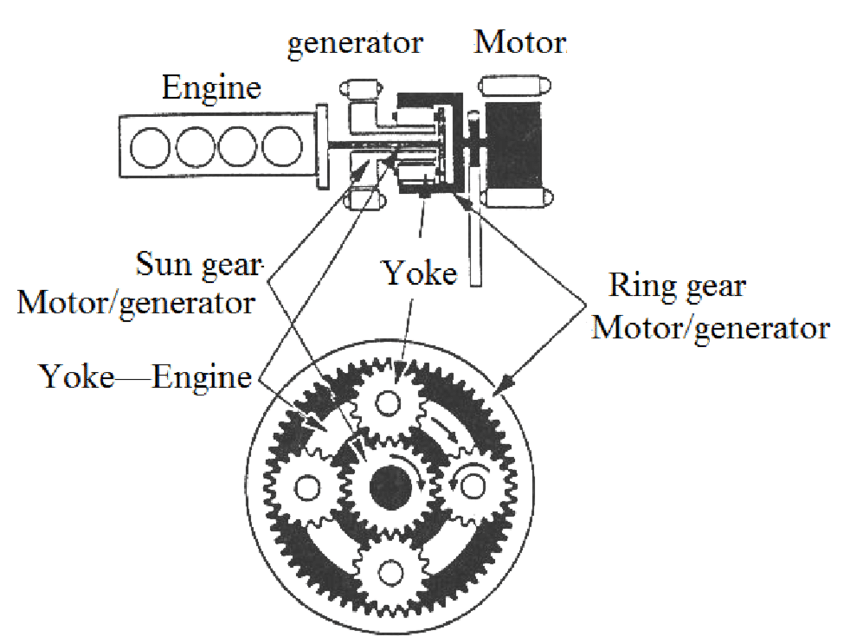

The core technology of the THS system lies in the Power Split Device, which dynamically coordinates the engine with dual motors through a single-row planetary gear set.

The planetary gear set consists of three components: the sun gear, planet carrier, and ring gear, which are connected to the generator (MG1), engine, and motor (MG2), respectively.

The engine's output power is divided into two paths: a mechanical path (which directly drives the wheels through the planet carrier) and an electrical path (which generates electricity via MG1, with the electric power driving MG2 or being stored in the battery).

The system's primary operating modes include:

EV Mode (Electric Vehicle Mode): The battery powers MG2 (the traction motor) to drive the wheels while the engine remains off.

Hybrid Mode (Power Split Mode): The engine drives the wheels directly with a portion of its power, while the remaining power is used to drive MG1 (the generator), producing electricity to power MG2 or charge the battery.

Engine Charging Mode: Excess engine power is used to drive MG1, which generates electricity to charge the battery.

Regenerative Braking Mode: During deceleration or braking, MG2 operates as a generator, converting the vehicle's kinetic energy into electrical energy to recharge the battery.

The fourth-generation THS system uses the 2ZR-FXE 1.8L Atkinson-cycle engine, achieving a 40% thermal efficiency.

Through optimizations in the P610 E-CVT transmission, including its gear ratio and motor control algorithm, the overall system's thermal efficiency is increased to 41% .

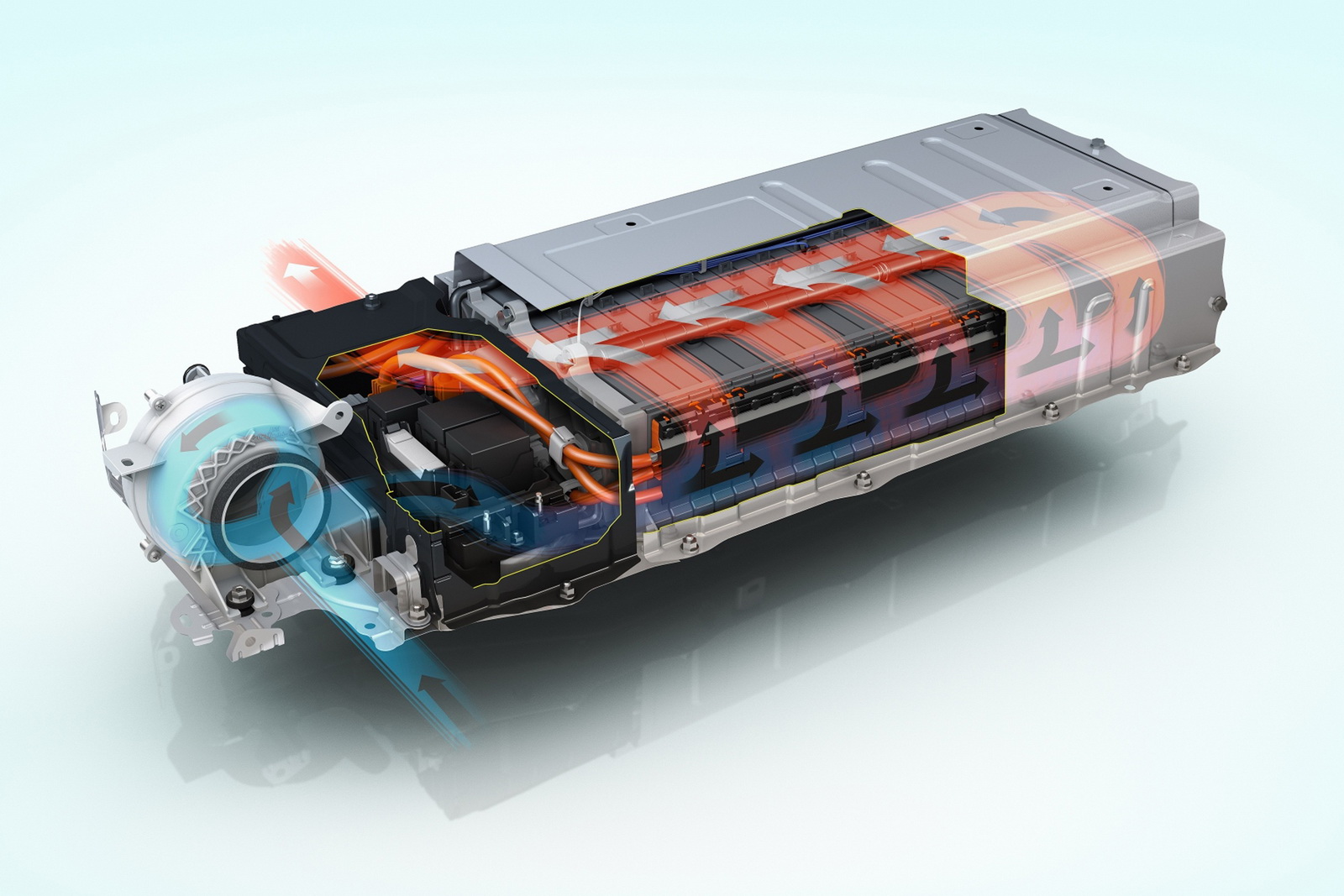

The Ni-MH (nickel-metal hydride) battery pack features a bipolar structure, which reduces internal resistance and enhances power density.

This system operates without the need for external charging; all its energy is sourced from the engine operating within its high-efficiency range and from regenerative braking.

Hybrid MAX High-Performance Parallel Hybrid System

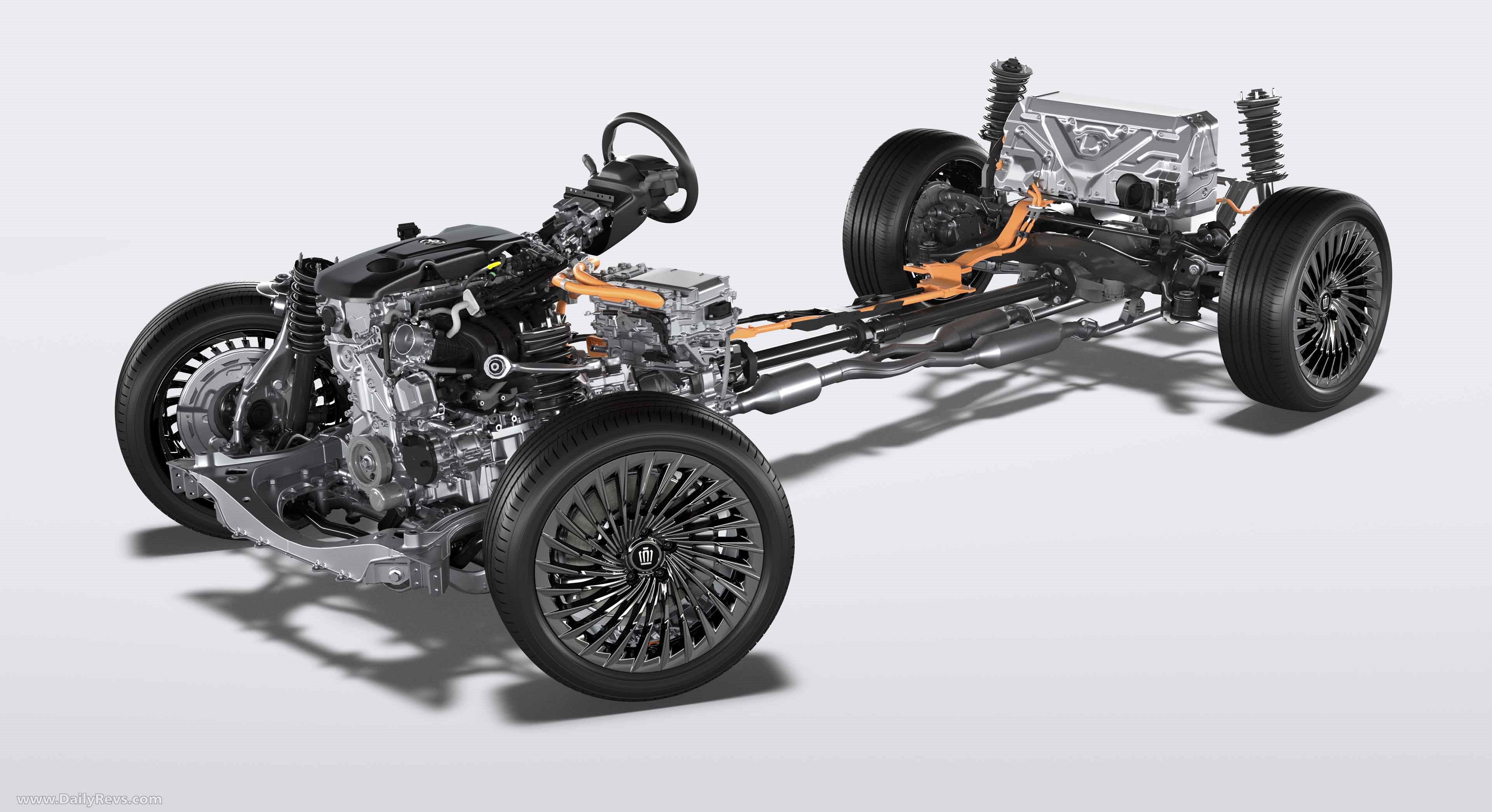

Hybrid MAX adopts a P2 parallel architecture, which is fundamentally different from the power-split nature of traditional THS.

The system consists of a turbocharged engine (2.4T or 3.5T), a front motor, a wet multi-plate clutch, and a 6AT transmission.

The motor is located between the engine and the transmission, and coupling/decoupling with the engine is achieved through the clutch.

Technical Principle Features:

Power coupling method: The K0 clutch controls the connection between the engine and the motor, while the K1 clutch manages the input to the transmission;

Torque stacking mechanism: The torque of the engine and motor is directly combined on the transmission input shaft, with a maximum combined output of up to 367 horsepower;

Transmission system: Uses Direct Shift-6AT transmission, maintaining a mechanical shifting mechanism, and supports engine direct drive;

Battery system: The bipolar nickel-metal hydride battery reduces internal resistance, supporting higher charge and discharge power (30% improvement over traditional batteries).

The four-wheel-drive system adopts an eAxle electronic rear axle, with the independent rear axle motor providing up to 30% additional torque distribution. The system always ensures dual power sources working simultaneously, differing from the THS operation mode switching strategy, to ensure sustained high-performance output.

i-FORCE MAX Off-Road Dedicated Hybrid System

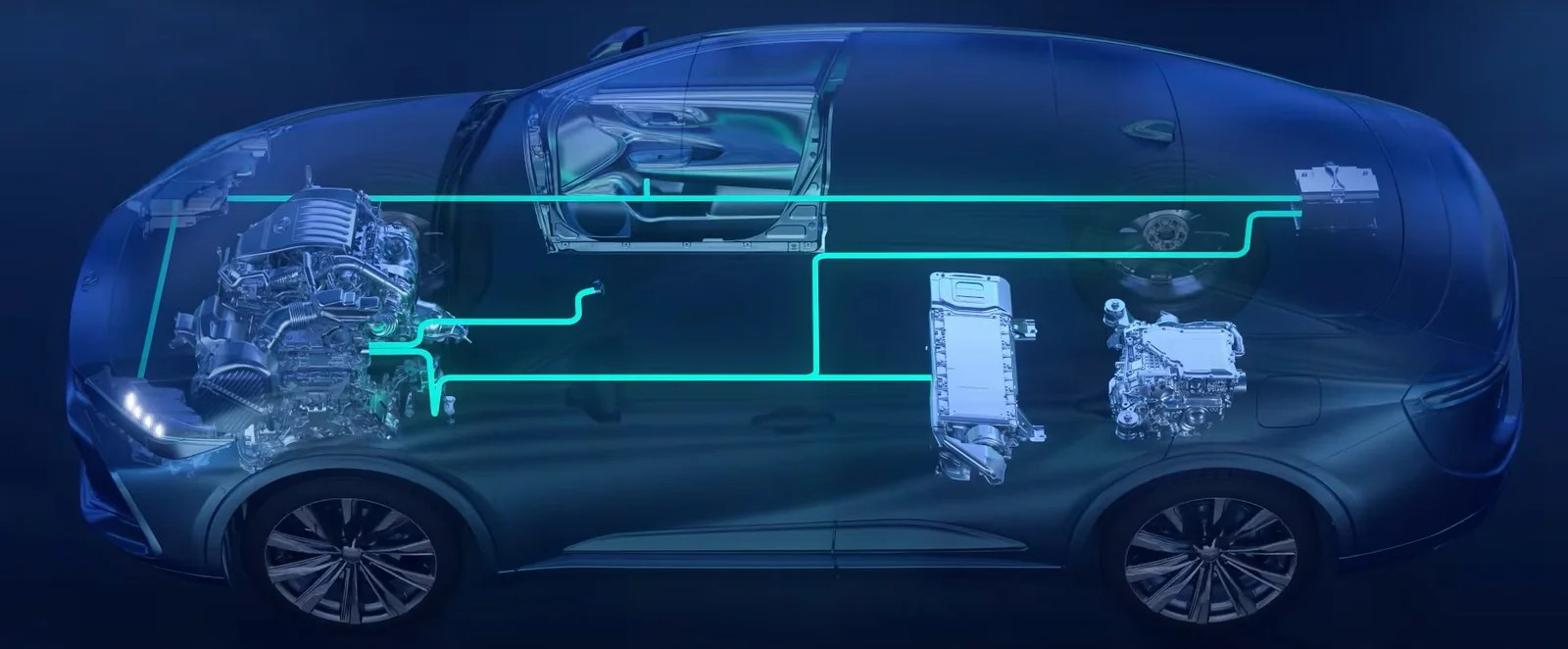

The i-FORCE MAX adopts a longitudinal P2 hybrid architecture, optimized specifically for high torque demands and off-road scenarios.

The system consists of a turbocharged engine (3.5T V6 or 2.4T L4), an integrated electric motor, a longitudinal automatic transmission (8AT/10AT), and a mechanical four-wheel drive system.

Core Technical Principles:

Electric motor integration position: The motor is directly connected to the transmission input shaft via a spline and is located between the engine flywheel and the transmission;

Torque assistance mechanism: The motor provides peak torque compensation at low engine RPMs (maximum additional torque of 250N·m);

Transmission system: Retains traditional mechanical automatic transmission and transfer case, supporting low-speed four-wheel drive mode (torque magnification of 2.64 times);

Battery system: The 1.87kWh nickel-metal hydride battery pack is designed to resist vibrations and supports high-power discharge (maximum 80kW).

When the system is operating, the motor mainly undertakes three functions:

Starting the engine (replacing the traditional starter);

Providing pure electric crawling capability during low-speed off-road driving;

Assisting with torque during acceleration. The mechanical full-time four-wheel-drive system achieves front and rear torque distribution (default 40:60) through the Torsen central differential, with a mechanical differential lock equipped on the rear axle.

PHEV Plug-in Hybrid System

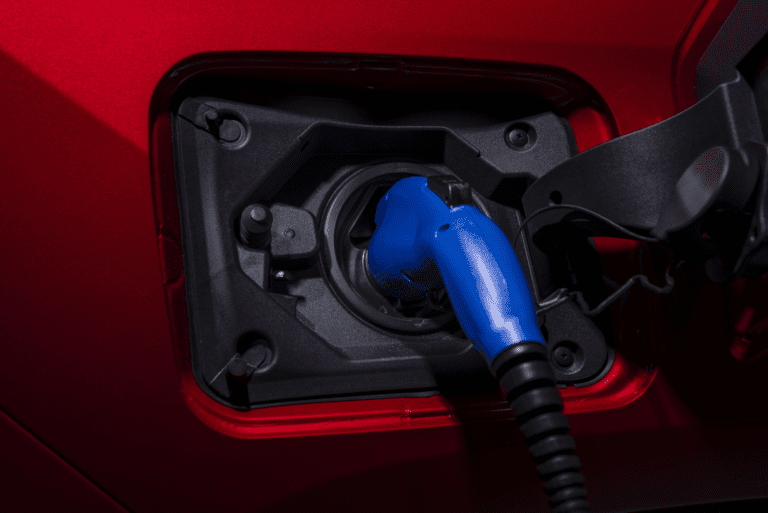

The Toyota PHEV system is upgraded based on the THS architecture, with core improvements in a large-capacity lithium battery pack and external charging functionality.

The sixth-generation system uses a 2.5L Atkinson cycle engine (thermal efficiency of 41%) combined with dual motors, and the battery capacity has been increased to 18.1kWh or more. (RAV4 Prime).

EV Mode: The battery powers both front and rear electric motors, delivering a combined peak output of 134 kW and achieving a top speed of 135 km/h.

Hybrid Mode: It operates on a similar principle to the THS system, but features a higher engine engagement threshold (the engine typically activates only when the battery State of Charge (SOC) drops below 20%).

Charging Control: The system is equipped with a DC-DC converter and supports 50 kW DC fast charging, enabling a charge from low to 80% SOC in approximately 30 minutes.

Thermal Management: The battery pack utilizes a liquid cooling system designed to maintain the cells within their optimal operating temperature range of 25°C to 35°C.

The upgrades to the electric drive system include the following:

The front motor's power has been increased to 88 kW, representing a 40% increase over the HEV variant.

The rear motor utilizes E-Four technology and delivers a maximum output of 40 kW.

The PCU (Power Control Unit) incorporates SiC (silicon carbide) power components, which reduce energy losses by 30%.

The system supports Vehicle-to-Load (V2L) functionality, enabling external power discharge of up to 1500 watts via the charging port.

Multi-Stage Hybrid System

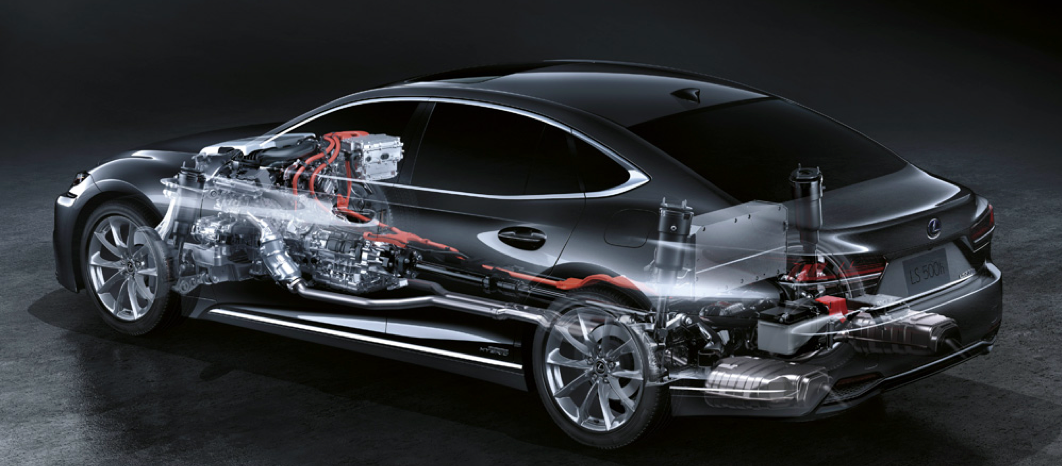

The Multi-Stage Hybrid System represents an advanced evolution of Toyota's hybrid technology, featuring an innovative design that effectively provides 10 preset gear ratios.

The system comprises a 2.5L Dynamic Force engine, a dual-motor setup (MG1 and MG2), and a multi-stage electro-mechanical transmission unit.

The engine utilizes an Atkinson-cycle design and is fitted with the VVT-iE (Electric Variable Valve Timing) system and a D-4S dual fuel injection system, achieving a remarkable thermal efficiency of 41%.

Technical Highlights:

The multi-stage transmission coordinates planetary gear sets with a clutch for precise engine speed matching;

The front electric motor delivers 131.9 kW and 300 N·m, while the rear motor provides 40 kW and 121 N·m;

The high-power Ni-MH (nickel-metal hydride) battery has a volume that is 67% smaller than earlier generations, along with a significantly higher energy density;

The E-Four AWD system enables intelligent front/rear torque distribution, ranging from 100:0 to 20:80;

In operation, the multi-stage transmission contributes to a smoother, more linear acceleration process and reduces the 0-100 km/h sprint time compared to conventional THS systems.

The engine always operates in the optimal efficiency range, with a combined fuel consumption reduced by more than 30% compared to conventional gasoline vehicles with the same displacement. This technology is mainly applied to high-end models such as the Crown Sedan and Lexus NX350h.

Technical Comparison of Toyota's Five Hybrid Systems

| Parameter | THS | Hybrid MAX | i-FORCE MAX | PHEV | Multi-Stage HEV |

| Architecture Type | Power Split | Parallel | Longitudinal Parallel | Extended Power Split | Multi-Stage Power Split |

| Transmission Type | E-CVT | 6AT | 8AT/10AT | E-CVT | Multi-Stage E-CVT |

| System Combined Power | 90-160kW | 270kW | 325-443kW | 225-302kW | 179-239kW |

| Battery Type | Nickel-Metal Hydride | Bipolar Nickel-Metal Hydride | Nickel-Metal Hydride | Lithium-Ion | High-Power Nickel-Metal Hydride |

| Pure Electric Range | None | <2km | <3km | 68-95km | <5km |

| Core Application Scenarios | Urban Commuting | High-Performance Highway | Off-Road Towing | Long-Distance Pure Electric Driving | Luxury and Comfort |

Toyota has achieved a comprehensive layout of hybrid technologies through these five technical solutions: THS pursues ultimate energy efficiency, Hybrid MAX emphasizes performance, i-FORCE MAX focuses on off-road reliability, PHEV extends electrified travel range, and Multi-Stage HEV creates a luxurious driving experience.

Toyota has mastered three types of hybrid technology architectures

Through classification, we can identify that Toyota has mastered three types of hybrid technology architectures: THS, i-FORCE MAX, and Hybrid MAX.

PHEV and Multi-Stage HEV are technology solutions derived from THS and belong to the same type of technical architecture.

The reason for this classification is that THS, PHEV, and Multi-Stage HEV all utilize the planetary gearset (Power Split Device, PSD) as a core component.

PHEV is straightforward; Toyota improved the motor power and battery capacity to enhance the pure electric driving speed and range.

The Multi-Stage HEV system, however, is more complex. It represents an advanced evolution of Toyota's THS (Toyota Hybrid System) architecture.

It builds upon the standard THS E-CVT by integrating an additional 4-speed automatic transmission unit, which, through sophisticated electronic control, creates the effect of 10 distinct gear ratios.

This combination of a traditional mechanical gearbox and the planetary gear set overcomes inherent limitations of the conventional THS system, particularly in acceleration response and high-speed fuel efficiency, while retaining the core fuel efficiency benefits of the THS design.

This system is suitable for Toyota's high-end models, such as the Crown Sedan and Lexus NX350h, balancing power and luxury experience.

All the hybrid systems introduced above share Toyota's core energy management algorithms, but have been specifically optimized in hardware architecture according to their positioning differences.

With the acceleration of electrification, these systems will continue to evolve, integrating lithium-ion batteries, higher-power motors, and other technologies to maintain Toyota's leading advantage in the hybrid field.

If any infringement occurs, please contact us for deletion

Trending News

2026 New Proton S70 Upgrades from Three-cylinder to Four-cylinder, Significantly More Powerful!

Proton's 2026 S70 to be launched before Lunar New Year, with a key upgrade to a 1.5-liter four-cylinder turbocharged engine replacing the three-cylinder model, improving power smoothness, maintaining spaciousness, with the infotainment system and driver assistance possibly adapted to local road conditions, offering practical improvements tailored to the needs of Malaysian and Thai family users, aiding car purchase decisions.

BYD to unveil new technologies on March 5, 2026 – pure EV range to exceed 1,000 km

This isn’t about a new model debut. Instead, BYD is preparing to showcase a suite of near-production core technologies – including a pure EV boasting a CLTC range of over 1,000 km, an upgraded Megawatt Flash Charging 2.0 system, and the next-generation DM 6.0 Super Hybrid platform.

In 2026, Should I Buy a Proton X50 or a Perodua Traz? Can the RM 6,000 Rebate Offset the Traz's Space Advantage?

Recently, one of the most frequently asked questions in the Malaysian market is: So, should you go for the Proton X50, which offers stronger performance and a greater sense of technology, or the Perodua Traz, which provides more space and is more budget-friendly? Especially considering the X50 has discounts of up to around RM 6,000, how significant is the price difference left to weigh? This article provides an objective analysis from the perspective of daily usage.

Toyota Estima to return in 2026?

Since it was discontinued in 2019, news about the return of the Toyota Estima to the market has never stopped. Although Toyota has not yet released any official announcements regarding mass-production vehicles, the related information does not come from scattered rumors but originates from continuous revelations by Japanese automotive media.

Donut Lab Announces Mass-Produced All-Solid-State Battery, Claims 5-Minute Full Charge

All-Solid-State Battery, which has long remained in the laboratory and concept stages, is now approaching a true commercialization milestone. Donut Lab announced that its All-Solid-State Battery is ready for mass production and will be first equipped on the Verge TS Pro electric motorcycle.

Popular Cars

Model Year

Car Compare

Car Photo