Understanding BYD's Blade Battery: Safety and Innovation

Kevin WongFeb 23, 2024, 07:25 PM

Kevin WongFeb 23, 2024, 07:25 PM

When it comes to BYD's blade battery, touted as a safer alternative, what sets it apart?

Here are two key points to grasp from this technical piece.

1. What exactly is a blade battery?

A blade battery represents a battery structure that enhances volume utilization by altering the layout of battery cells. Compared to conventional battery packs of the same size, blade batteries offer larger capacities and translate to extended range capabilities.

2. What lies at the core of blade battery safety?

Blade battery safety hinges on the use of lithium iron phosphate (LFP) batteries, perging from the widely used ternary lithium batteries in passenger vehicles. LFP batteries exhibit superior stability.

So, what exactly is BYD's blade battery?

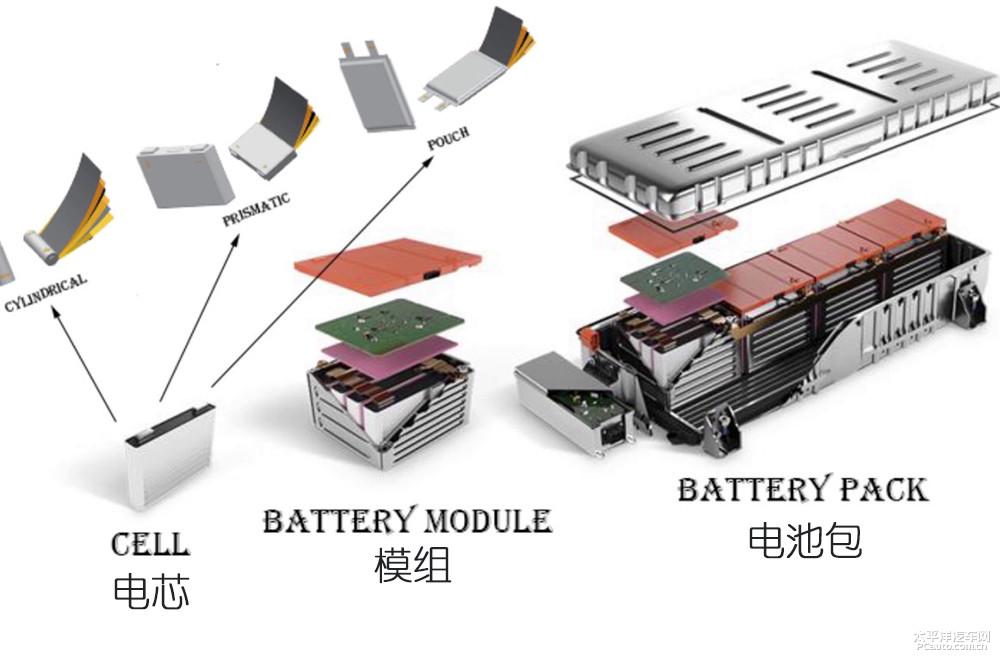

Traditional electric vehicle (EV) battery packs typically consist of modules composed of multiple battery cells. These modules are then assembled onto a casing with crossbeams and longitudinal beams, forming a battery pack. This three-tier assembly model, from cells to modules to the casing, occupies valuable space within the battery pack, limiting energy density improvement.

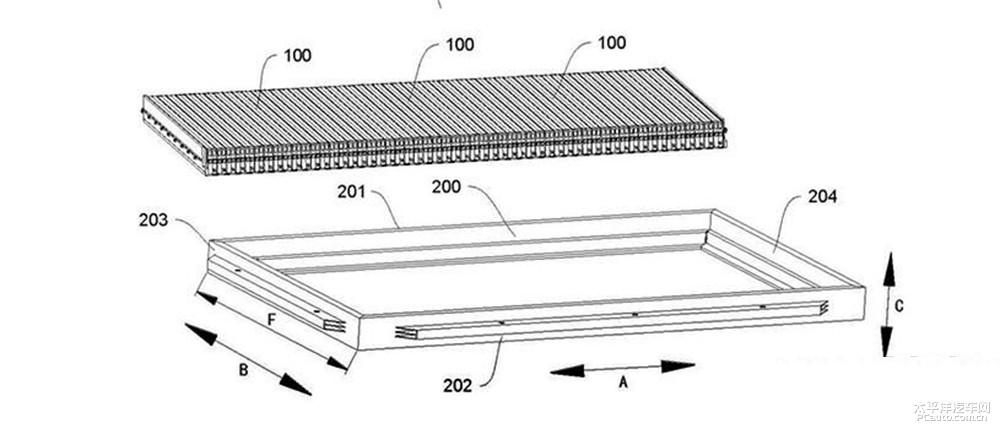

On the other hand, the "blade battery" employs the Cell to Pack (CTP) design, eliminating the intermediate module stage by directly integrating battery cells into the battery pack. Disassembling the battery pack of the BYD Atto3 reveals a stack of inpidual batteries measuring one meter in length, ten centimeters in width, and less than two centimeters in thickness. These batteries are tightly arranged, resembling "blades" inserted into the battery pack, hence the name "blade battery."

Moreover, the internal structure of the battery pack minimizes crossbeams or longitudinal beams, with the thin, blade-like LFP batteries contributing to the overall structural strength of the pack. Consequently, the limited space within the battery pack allows for the installation of more battery cells, significantly enhancing volume utilization and overall pack capacity. Under the premise of using LFP cells, the blade battery structure elevates the capacity/range of LFP batteries to the same level as ternary lithium batteries.

Thus, the critical challenge that has long plagued the development of LFP batteries in the passenger vehicle sector has been addressed. A major drawback of LFP batteries is their low energy density, resulting in conventional battery packs using LFP being much larger than those using ternary lithium batteries for the same 600km pure electric range. However, while ternary lithium batteries boast high energy density, their stability is inferior, consequently compromising safety.

Why not use ternary lithium batteries for blade batteries?

In fact, ternary lithium batteries can also be configured into a blade battery structure. However, the main reason BYD did not opt for the ternary lithium route lies in its inferior heat resistance compared to LFP materials. To compensate for the poor thermal safety of ternary lithium batteries, more space needs to be allocated for firewalls in battery pack design.

What advantages does using LFP cathode material offer? Among the two mainstream battery materials commonly used in EVs, LFP possesses four major advantages: high ignition temperature, slow heat release, minimal heat generation, and the absence of oxygen release during decomposition, making it difficult to ignite. For instance, at 500°C, the structure of LFP material remains stable, whereas ternary lithium material undergoes decomposition at around 200°C, triggering a vigorous chemical reaction that releases oxygen molecules, leading to thermal runaway.

However, LFP material also has its limitations. In extremely low-temperature environments, ternary lithium exhibits significantly higher discharge capacity than LFP. At -20°C, the discharge capacity of LFP is considerably reduced. Additionally, under conditions of low temperature and low state of charge, the charging power of LFP is lower than that of ternary lithium, making low temperatures the nemesis of LFP.

Nevertheless, such concerns are unwarranted in our driving environment, as extreme low-temperature conditions are non-existent, alleviating worries about battery performance degradation.

If any infringement occurs, please contact us for deletion

Trending News

2026 New Proton S70 Upgrades from Three-cylinder to Four-cylinder, Significantly More Powerful!

Proton's 2026 S70 to be launched before Lunar New Year, with a key upgrade to a 1.5-liter four-cylinder turbocharged engine replacing the three-cylinder model, improving power smoothness, maintaining spaciousness, with the infotainment system and driver assistance possibly adapted to local road conditions, offering practical improvements tailored to the needs of Malaysian and Thai family users, aiding car purchase decisions.

BYD to unveil new technologies on March 5, 2026 – pure EV range to exceed 1,000 km

This isn’t about a new model debut. Instead, BYD is preparing to showcase a suite of near-production core technologies – including a pure EV boasting a CLTC range of over 1,000 km, an upgraded Megawatt Flash Charging 2.0 system, and the next-generation DM 6.0 Super Hybrid platform.

In 2026, Should I Buy a Proton X50 or a Perodua Traz? Can the RM 6,000 Rebate Offset the Traz's Space Advantage?

Recently, one of the most frequently asked questions in the Malaysian market is: So, should you go for the Proton X50, which offers stronger performance and a greater sense of technology, or the Perodua Traz, which provides more space and is more budget-friendly? Especially considering the X50 has discounts of up to around RM 6,000, how significant is the price difference left to weigh? This article provides an objective analysis from the perspective of daily usage.

Toyota Estima to return in 2026?

Since it was discontinued in 2019, news about the return of the Toyota Estima to the market has never stopped. Although Toyota has not yet released any official announcements regarding mass-production vehicles, the related information does not come from scattered rumors but originates from continuous revelations by Japanese automotive media.

Donut Lab Announces Mass-Produced All-Solid-State Battery, Claims 5-Minute Full Charge

All-Solid-State Battery, which has long remained in the laboratory and concept stages, is now approaching a true commercialization milestone. Donut Lab announced that its All-Solid-State Battery is ready for mass production and will be first equipped on the Verge TS Pro electric motorcycle.

Popular Cars

Model Year

Car Compare

Car Photo