Why is the facelifted GR Yaris considered the finished product?

AshleyNov 21, 2025, 11:45 AM

AshleyNov 21, 2025, 11:45 AM

[PCauto] Over the past few years, if one were to select a car that truly captivates automotive enthusiasts, the GR Yaris would undoubtedly be at the forefront.

[PCauto] Over the past few years, if one were to select a car that truly captivates automotive enthusiasts, the GR Yaris would undoubtedly be at the forefront.

It is neither an expensive flagship model nor a high-volume mainstream vehicle; however, since its launch in 2020, it has swiftly become a sensation within the automotive community:

- It features a three-cylinder engine, yet delivers power that exceeds its class expectations;

- It incorporates a four-wheel-drive system while maintaining compact, and even ultra-compact, dimensions;

- It is an affordable hot hatch, yet carries a strong WRC homologation flavor.

Many, therefore, believed that the GR Yaris was a "finished product" at its launch. However, time has proven otherwise.

In 2024, following the introduction of the GR Yaris facelift (known as Gen 2), nearly everyone who closely examined the vehicle observed:

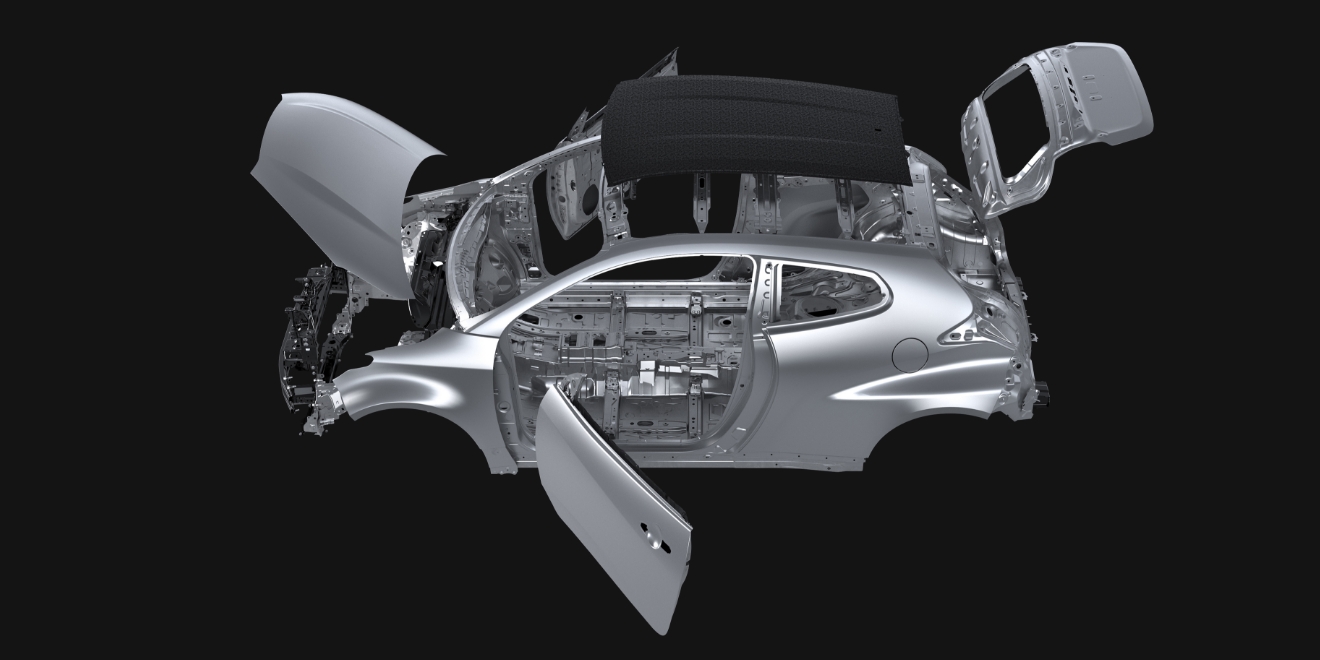

Toyota not only implemented interior modifications (such as incorporating a vertical handbrake) but also went far beyond what is typically considered a "minor facelift." his entails a comprehensive re-engineering at the structural level of the body-in-white, including increased spot welding, the application of structural adhesives, reinforcement of suspension mounting points, upgrades to the cooling system, and enhancements to the powertrain's durability...

Any one of these undertakings alone would constitute a significant engineering project.

If the first generation was already so exceptional, why would Toyota invest such significant effort?

What are the changes in the GR Yaris facelift?

Upgraded chassis rigidity, increased spot welding, and structural adhesives

One of the key highlights of Gen 2 is the substantial improvement in body rigidity.

The increased number of spot welds tightens the connections between steel plates, ensuring that the chassis retains its intended shape during every maneuver, thereby enabling more precise suspension movements.

Meanwhile, a significant amount of structural adhesive has been applied to critical areas such as the sills, A-pillars, and suspension mounting points (areas where the first generation exhibited weaknesses during intense driving). This treatment effectively transforms the body into a more monolithic structure. This significantly reduces micro-twists in the chassis during high-speed cornering.

Precise Matching of Power and Suspension

In addition to chassis rigidity, Toyota has also meticulously optimized the powertrain and suspension system. The manual transmission received revised gear ratios and a reinforced clutch for a smoother, more natural feel, while the automatic version gained improved responsiveness and durability.

The suspension geometry has been finely tuned to complement the enhanced vehicle body, and the increased stiffness of the anti-roll bar offers greater body stability during high-speed cornering.

These collective adjustments ensure all vehicle systems work in harmony at the limit, allowing the driver to perceive a marked improvement in the unity between chassis and powertrain.

Driving Experience and Thermal Management Optimization

To ensure that high performance can be fully realized during extended periods of intense driving, the cooling system of Gen 2 has also been upgraded.

A larger intercooler and optimized water cooling system help the engine maintain stable output on track or mountain roads.

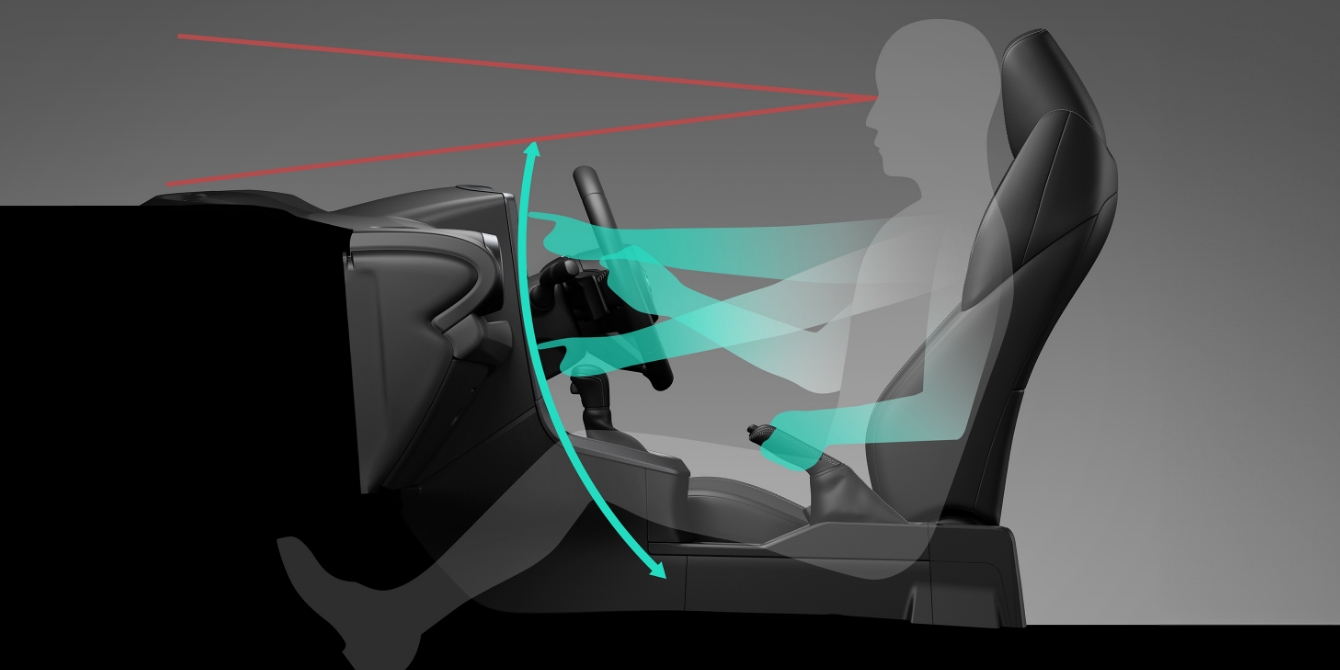

Additionally, slight adjustments to the seat position, enhanced steering feel, and optimized infotainment and instrument panel details provide the driver with a more intuitive sense of the improvements brought by the strengthened chassis.

With the Gen 2, Toyota has not only made surface-level improvements but also conducted a deep overhaul from the frame to the powertrain. Every enhancement serves a single core objective: unlocking the GR Yaris's full potential under extreme driving conditions.

Why is Toyota Enhancing the Rigidity of the GR Yaris Body?

The focal point of the GR Yaris Gen 2 facelift is the significant improvement in body rigidity. But why has Toyota placed such a strong emphasis on this aspect?

WRC Experience Exposes Chassis Weaknesses

The GR Yaris was born from WRC homologation requirements, meaning it must excel in racing-grade environments.

While the Gen 1 offered powerful performance and precise all-wheel drive, the chassis still exhibited slight flex during high-speed cornering and intense loads.

This minor deformation, negligible in daily driving, could cause the suspension geometry to deviate from its optimal design on track, compromising grip and steering feedback.

Toyota is acutely aware that the potential of suspension, tires, and four-wheel-drive systems is ultimately constrained by body rigidity. Therefore, enhancing overall body strength has become a top priority.

The Importance of Chassis-Suspension Coordination

In high-performance compact cars, every millimeter of suspension movement depends on the stable support of the chassis. A soft body can lead to delayed steering response, compromise tire grip, and result in a slight drifting sensation during high-speed cornering.

Gen 2 enhances chassis rigidity to complement the suspension by increasing spot welding, utilizing extensive structural adhesives, and reinforcing key nodes. This ensures that every steering input and load change is accurately transmitted to the tires.

This means that what the driver experiences during intense handling is predictability and controllability, rather than a sluggish response of the chassis "eating" its potential.

Why Didn’t Toyota Initially Improve the Body Rigidity of the GR Yaris

Japanese Automakers Often Overlook the Importance of Body Rigidity

To understand the deeper meaning behind the revision of the GR Yaris, we must revisit the development logic of Japanese performance cars.

For an extended period, the chassis design of JDM performance cars has exhibited notable differences from their European counterparts. The root cause lies in the fact that most Japanese performance cars are modifications of family car platforms rather than being designed from the ground up as dedicated high-performance platforms.

This can be seen everywhere. For example, the early versions of the Mitsubishi Lancer Evolution series were built on the platform of the regular Lancer compact sedan.

Although equipped with a turbocharged engine, all-wheel drive, and reinforced suspension, the chassis essentially adhered to the design philosophy of a family car.

Similarly, the Subaru WRX STI was originally modified from the Impreza sedan platform. The same applies to the AE86 and the Honda Civic Type R.

Inherent to a family car chassis are certain flexibility and design limitations, which render these performance derivatives susceptible to slight torsional flex under high-speed continuous cornering and extreme loads, which limits the full potential of the suspension and tires.

This origin helps explain the traditionally lower emphasis Japanese manufacturers placed on chassis rigidity reinforcement.

Derived from utilitarian platforms, the development focus for these cars traditionally leaned toward lightweight design and agile handling, rather than deliberately strengthening the body rigidity.

Spot welding quantity, structural adhesive usage, and reinforcement of key areas rarely appear in early JDM mass-production cars because these modifications increase weight and cost, and most household car users don't require extreme handling performance.

This lightweight philosophy persisted for decades and has shaped the unique driving style of Japanese performance cars—agile, full of fun, but with potential weaknesses in extreme conditions.

European high-performance cars have focused on extreme handling experiences from the beginning

In contrast, most European high-performance cars are developed based on dedicated platforms, with considerations for chassis rigidity, structural nodes, and suspension layout for extreme handling factored in from the initial design stage.

The stability of the car body under high-speed long curves and continuous strain is prioritized, while weight and cost can be offset by higher price points.

This difference makes it challenging for Japanese performance cars, even with upgraded power and suspension, to match the chassis rigidity of European models in the same class.

It wasn't until the last decade that Japanese manufacturers began widely adopting structural adhesives and chassis reinforcement technologies in mass-production cars.

It is against this backdrop of evolving philosophy that the comprehensive upgrades to the GR Yaris Gen 2 gain their significance. Toyota has upgraded the GR Yaris from a potent hot hatch to a thoroughly engineered performance machine by increasing spot welds, extensively using structural adhesives, and reinforcing key points.

If any infringement occurs, please contact us for deletion

Trending News

Perodua Myvi and Bezza may undergo major upgrades in 2026

After the update, the Bezza will no longer be just a low-cost alternative but a core model in the Perodua system with greater market competitiveness and brand premium potential. The upgrade of the Myvi is not to be unconventional but to strengthen the brand and market, ensuring that the Myvi continues to maintain its irreplaceable position in the new round of product competition.

Perodua Traz VS Ativa, which one is more worth buying?

Traz, as a newly launched mid-sized SUV, offers more spacious room and mainstream power compared to small SUVs, but its pricing appears slightly higher than that of Ativa. Ativa, on the other hand, is Perodua's long-time best-selling small SUV with more affordable pricing and a balanced combination of power and tech features.

Perodua Traz 2025:Spec, Price and Features

Perodua Traz has been officially launched in Malaysia. It is a B-segment five-seater SUV built on the DNGA platform. Compared to the Yaris Cross, which emphasizes brand and quality, the Traz comes with a localized rate of about 95%, offering a more friendly price and practical features.

2026 Honda Jazz minor facelift exposed in the Chinese market, featuring a new front-end design

The fourth generation Honda Jazz (known as Fit in some markets) has maintained stable global sales since its launch in 2019, but its performance in the Chinese market has been less optimistic. Now, the Chinese market is about to welcome its second facelift. The new model has undergone significant upgrades in exterior and interior design, while retaining the current 1.5L naturally aspirated engine and CVT transmission system.

Proton e.MAS 7 OTA upgrades to Flyme Auto 1.2.0, completing the Android Auto interconnection ecosystem

Proton has officially released the Flyme Auto 1.2.0 version OTA update for e.MAS 7 users. The core of this upgrade is the addition of support for Android Auto, offering both wired and wireless connection options. Combined with the previously integrated Apple CarPlay feature, it achieves full coverage of the two major smartphone ecosystems, Android and Apple. This marks a step towards perfecting the smart cockpit experience of the e.MAS 7 all-electric SUV and is also a key milestone in Proton's phased software iteration plan.

Popular Cars

Model Year

Car Compare

Car Photo