GAC Aion Ruipai Factory Completes Construction, Produces Palm-Sized Electric Drive Unit?

Kevin WongFeb 23, 2024, 07:25 PM

Kevin WongFeb 23, 2024, 07:25 PM

Although Guangzhou Automobile Aion may still be unfamiliar to many consumers, it is a powerful player among Chinese new energy brands. Born from Guangzhou Automobile Group, Aion specializes in producing pure electric vehicles and has many users in the Chinese market. It also has its own high-end brand: Hyper.

Currently, the AION Y PLUS and AION ES available in China are models under Guangzhou Automobile Aion, but Hyper brand models have not yet entered the domestic market.

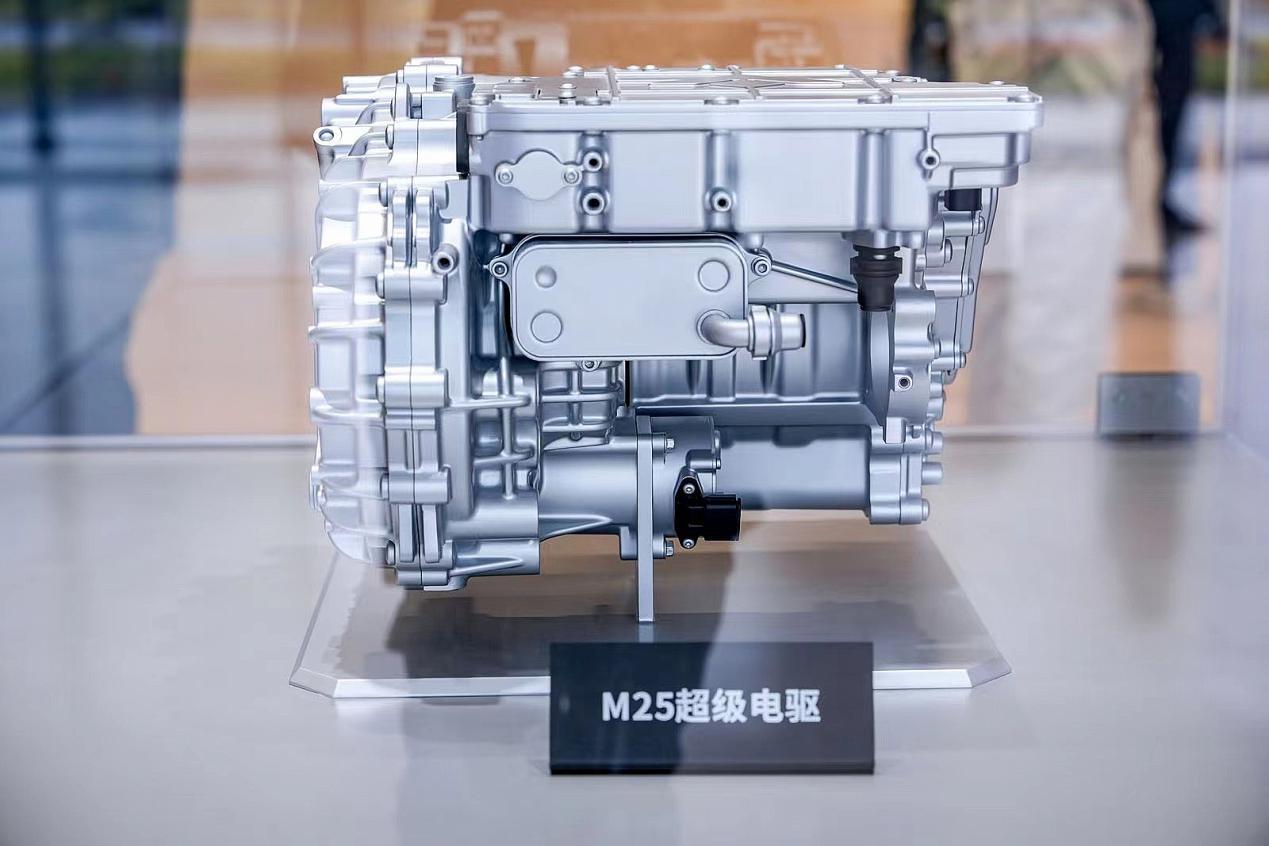

The M25 produced by Guangzhou Automobile Aion Ruipei Smart Ecological Factory is a super electric drive unit using Quark electric drive technology and is only installed in Hyper brand models. However, there is no need to be disappointed, as Guangzhou Automobile Aion has stated that the M25 electric drive unit will also be considered for installation in its own models. As its flagship model, the AION Y PLUS might have a good chance of getting it!

What do we need to know about the M25 super electric drive unit?

1. This is a high-performance electric motor independently developed and produced by Guangzhou Automobile Aion.

2. It has a maximum speed of up to 22,000 rpm, with power output comparable to a V8 engine.

3. It is over 20 kilograms lighter than mainstream products on the market.

Why miniaturize and lighten the M25 motor?

When you see the actual product, you will find that the size of the Ruipei M25 super electric drive unit is not large. Compared with mainstream products, the internal motor is almost half the size, and it can even be held in one hand. However, its power density is as high as 12 kW/kg—industry average is only around 6 kW/kg. M25 doubles this level—coupled with its maximum speed of 22,000 rpm, its power output level is comparable to that of a traditional V8 engine. Therefore, the official has given the M25 super electric drive unit the nickname "Palm-sized V8" for its balance of small size and strong power.

You might ask: Does it make a difference if the motor is smaller or larger? Does it matter if the motor is a bit smaller or larger when it comes to the car? Of course, it matters. For manufacturers, a smaller motor means using less material, smaller equipment for the motor production line, lower energy consumption in the production process, and lower carbon emissions... All these reductions add up to cost savings. Therefore, many manufacturers are pursuing motor miniaturization from the perspective of directly reducing costs.

You may also wonder: if the motor is smaller, doesn't that mean the power output is also smaller? This is where technological development comes into play—through technological advancements, there are new changes in the use of motor materials, optimization of manufacturing processes, and significant increases in energy density and power density. Technological progress is disruptive, making it possible for a smaller motor to have even more powerful output after shrinking.

Hyper has recently launched a pure electric sports car called the SSR, which has limited space in its body but can still accommodate three small motors, achieving a 1.9-second acceleration from 0 to 100 km/h. If it were ordinary motors, it would be impossible to fit three, which shows the disruptive effect of technological progress.

How does the M25 achieve all this?

As the first mass-produced product from the Ruipei factory, the M25 super electric drive unit features three leading technologies in the industry, corresponding to materials, motors, and electronic control.

First, let's look at the materials. The M25 super electric drive unit is equipped with independently developed high-voltage silicon carbide modules, which can adapt to 900V high voltage and are small in size, meeting the requirements for miniaturization.

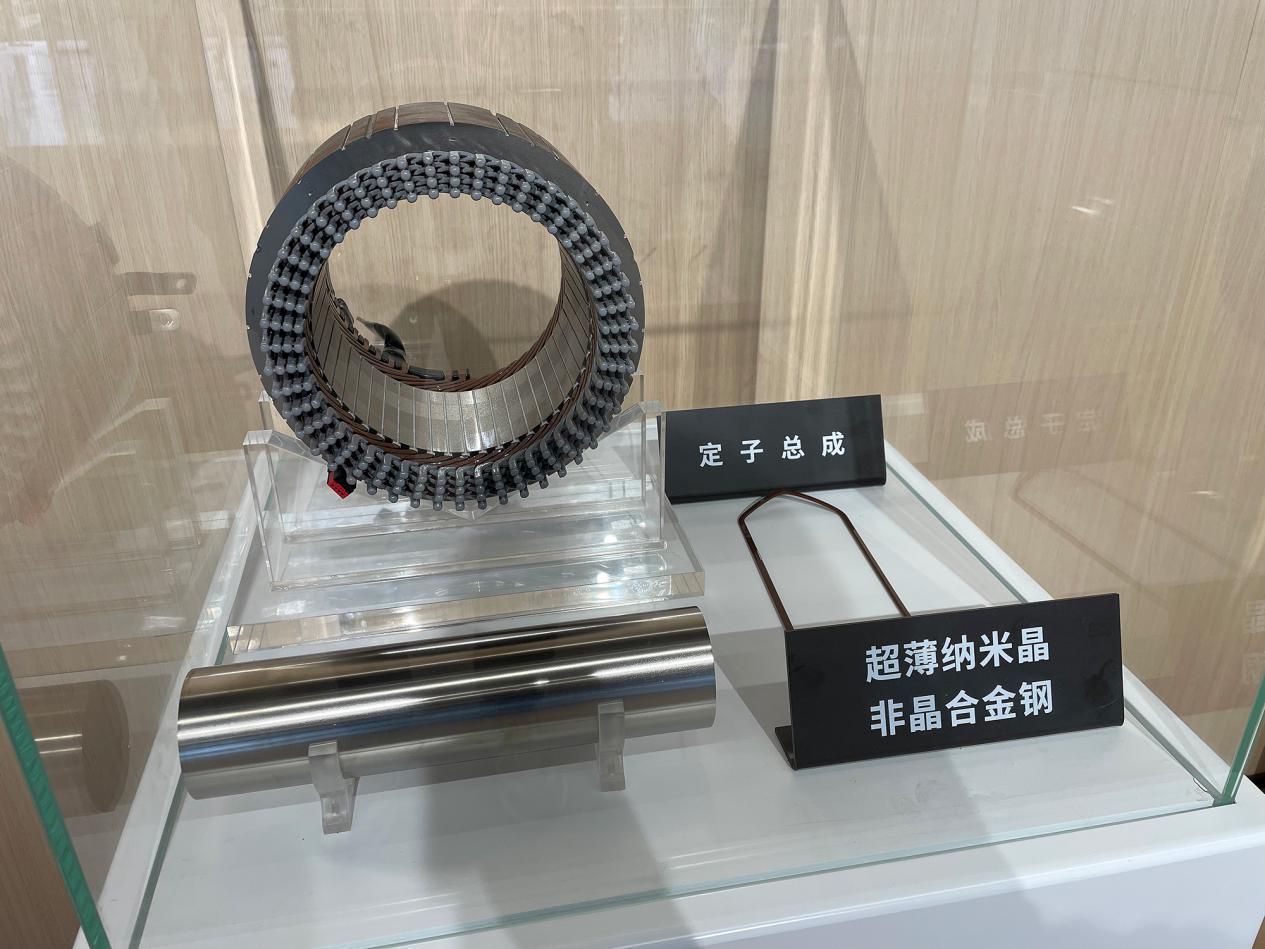

It uses nano-crystalline-non-crystalline alloy materials (new silicon steel), which are ultra-thin and have low losses. Aion uses this new material to make the motor stator iron core, reducing the motor's iron core loss by 50%, effectively reducing motor energy loss, improving motor operating efficiency to 97.5%, and achieving a maximum motor efficiency of 98.5%. Rare earth magnetic steel materials can also allow the motor to meet both high power and low cost requirements.

Next is motor technology. The M25 super electric drive unit's motor can operate at a speed of up to 22,000 rpm, claiming to be the world's first mass-produced high-speed motor, while the current industry production level is at 18,000 rpm. The ability to achieve such high speeds relies on Aion's patented X-PIN flat wire stator technology and carbon fiber high-speed rotor technology, which can reduce the motor's volume by 50% and increase power density by 100% through optimized flat wire winding methods. In terms of actual weight, the M25 super electric drive unit's motor is over 20 kilograms lighter than mainstream products on the market.

Finally, there is electronic control algorithm technology. The M25 super electric drive unit adopts the industry's first high-voltage miniR-PWM control algorithm technology, which reduces motor current ripple by about 10% and improves efficiency through freedom release, comprehensive switch frequency, dead time allocation, and spatial vector selection optimization. This technology is suitable for the 900V platform and achieves a working condition efficiency of 92.5% for the M25 super electric drive unit through methods such as efficiency improvement of electronic control algorithm, motor design, and efficiency improvement of light-load transmission system.

The highly autonomous industrial chain is the biggest highlight of Guangzhou Automobile Aion

We know that BYD has always had outstanding advantages in independent research and development and production. For example, it can independently develop and produce vehicle-grade IGBT chips and blade batteries.

The advantage of a highly autonomous industrial chain is lower and more controllable costs, controllable quality, and better adaptability. If the core components of a car are independently developed and produced, its matching degree will be higher than that of a car assembled from various products, and naturally, the vehicle's performance and quality will be more reliable.

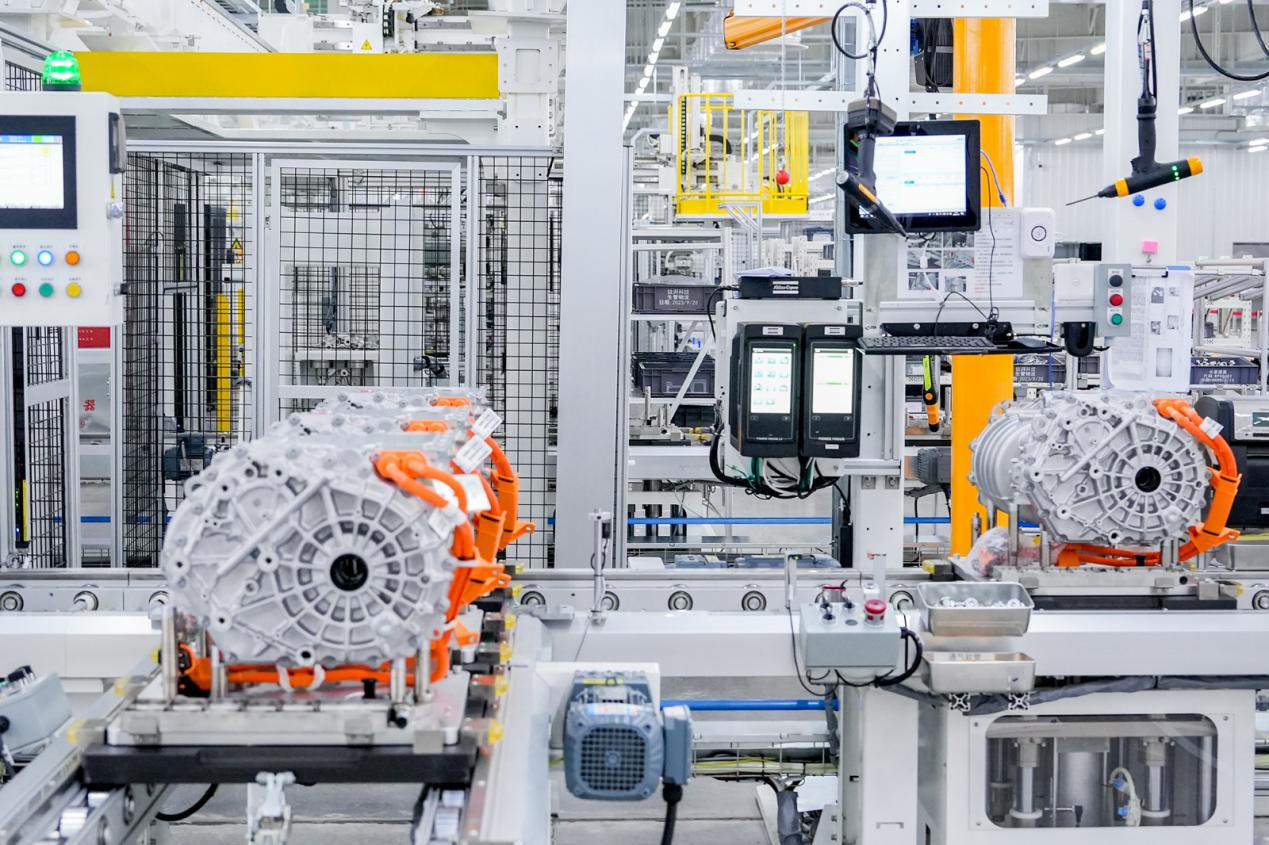

The fierce competition in the Chinese market has led many domestic brands to seek autonomy in their industrial chains. The start of production at the Ruipei Smart Electric Drive Factory means that Guangzhou Automobile Aion has achieved full self-research and production of the three-electric system.

From the perspective of self-research and production of the entire chain, Guangzhou Automobile Aion's own production of electric drive systems is indeed the most cost-effective method—it can not only create performance-matched electric drive systems for its own products, which are more targeted than off-the-shelf generic products but also eliminate waste. Some additional things that are unavoidable when sourcing externally can be omitted, successfully reducing costs and improving efficiency.

If we look at it from a short-term perspective, this change may not seem to have much impact on us, but in the long run, as Guangzhou Automobile Aion's factory in Thailand is completed and put into production, and its market share increases, the benefits brought about by these technological changes will naturally be enjoyed by us as well.

If any infringement occurs, please contact us for deletion

Trending News

2026 New Proton S70 Upgrades from Three-cylinder to Four-cylinder, Significantly More Powerful!

Proton's 2026 S70 to be launched before Lunar New Year, with a key upgrade to a 1.5-liter four-cylinder turbocharged engine replacing the three-cylinder model, improving power smoothness, maintaining spaciousness, with the infotainment system and driver assistance possibly adapted to local road conditions, offering practical improvements tailored to the needs of Malaysian and Thai family users, aiding car purchase decisions.

In 2026, Should I Buy a Proton X50 or a Perodua Traz? Can the RM 6,000 Rebate Offset the Traz's Space Advantage?

Recently, one of the most frequently asked questions in the Malaysian market is: So, should you go for the Proton X50, which offers stronger performance and a greater sense of technology, or the Perodua Traz, which provides more space and is more budget-friendly? Especially considering the X50 has discounts of up to around RM 6,000, how significant is the price difference left to weigh? This article provides an objective analysis from the perspective of daily usage.

Toyota Estima to return in 2026?

Since it was discontinued in 2019, news about the return of the Toyota Estima to the market has never stopped. Although Toyota has not yet released any official announcements regarding mass-production vehicles, the related information does not come from scattered rumors but originates from continuous revelations by Japanese automotive media.

Why do Malaysians prefer the Toyota 2NR-VE engine?

When choosing a family car in Malaysia, locals have an unwritten standard: "Don't look at how good the performance parameters are, just see if it can run smoothly for ten years."

Donut Lab Announces Mass-Produced All-Solid-State Battery, Claims 5-Minute Full Charge

All-Solid-State Battery, which has long remained in the laboratory and concept stages, is now approaching a true commercialization milestone. Donut Lab announced that its All-Solid-State Battery is ready for mass production and will be first equipped on the Verge TS Pro electric motorcycle.

Popular Cars

Model Year

Car Compare

Car Photo