What is the best-selling engine in the world right now? Technical analysis of the Toyota A25 series engine

AshleyOct 01, 2025, 11:00 AM

AshleyOct 01, 2025, 11:00 AM

[PCauto] Toyota, as a car manufacturer with an annual global sales volume exceeding 10 million units, has maintained its position as the global sales champion for five consecutive years. Toyota's engines are continuously running in various parts of the world along with these vehicles.

If you were to ask, which engine is the most important for this globally leading car manufacturer?

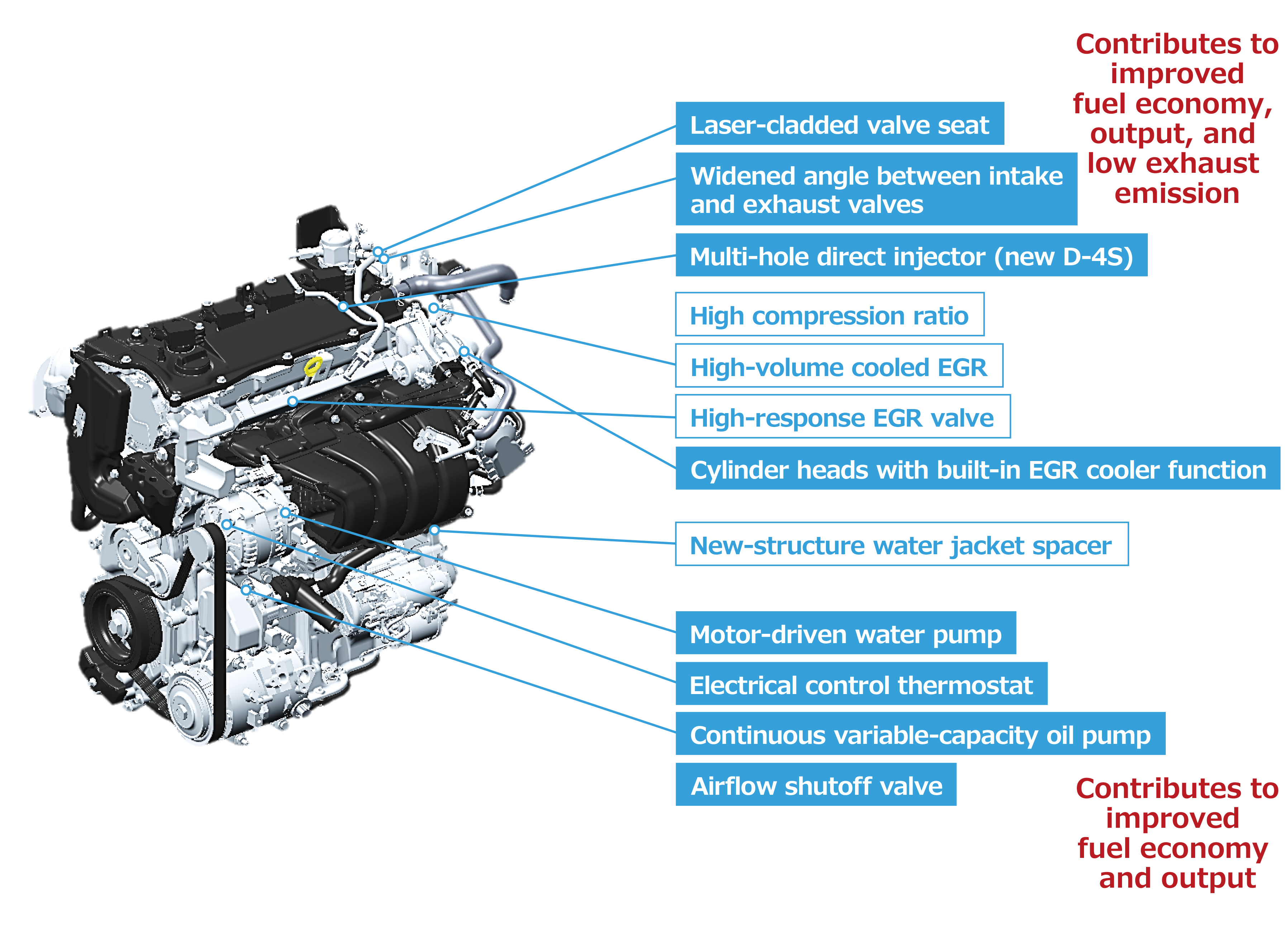

The answer is neither the classic 2JZ inline-six nor the first-generation Prius’s 1NZ-FXE hybrid engine—it is the A25 series engine under the TNGA platform. This engine series incorporates a multitude of Toyota's advanced processes and technologies, achieving an impressive 41% thermal efficiency.

The A25 series represents one of Toyota's most strategically vital engine families

This engine series powers over a dozen core models across both the Toyota and Lexus brands. Renowned for its balance of high thermal efficiency (up to 41% in hybrid variants), low fuel consumption, and proven reliability, it serves as a cornerstone of Toyota's global sales strategy.

In 2024 alone, vehicles equipped with the A25 series accounted for over 3 million global sales: the RAV4, with 1.187 million units sold, became the world's best-selling vehicle (surpassing the Tesla Model Y); the Camry secured nearly 600,000 sales, maintaining its leadership in the midsize sedan segment. Furthermore, the Highlander and Sienna achieved sales of approximately 450,000 and 250,000 units respectively, reinforcing their strong positions in their respective segments.

The widespread adoption of specific A25 variants across this diverse and successful model range directly underscores the series' profound strategic importance to Toyota.

The A25 series engine is the most thermally efficient civilian engine

The A25 series engine is a core member of the TNGA Dynamic Force Engine family and is also the ultimate engine under TNGA, shouldering the responsibility of powering flagship models.

According to TNGA's philosophy, Toyota aims to streamline over 800 types of old engines into 9 engine types and 17 versions through unified combustion models and standardization of key components (such as cylinder blocks and cylinder head structures). This is expected to achieve the goals of “30% improvement in R&D efficiency and 20% reduction in manufacturing costs.”

In terms of technical specifications, the A25 series engine targets high thermal efficiency: standard versions achieve a thermal efficiency of 40%, while hybrid versions reach 41%. Specific power output exceeds 60kW/L for standard versions and 50kW/L for hybrid versions.

These figures not only surpass traditional naturally aspirated engines (e.g., the Prius engine’s thermal efficiency is 40% but with a specific power output of only 40kW/L), but also outperform some turbocharged models, making it the most thermally efficient engine currently available on the market.

To withstand high compression ratios, the A25 series engine adopts innovative cylinder block technology

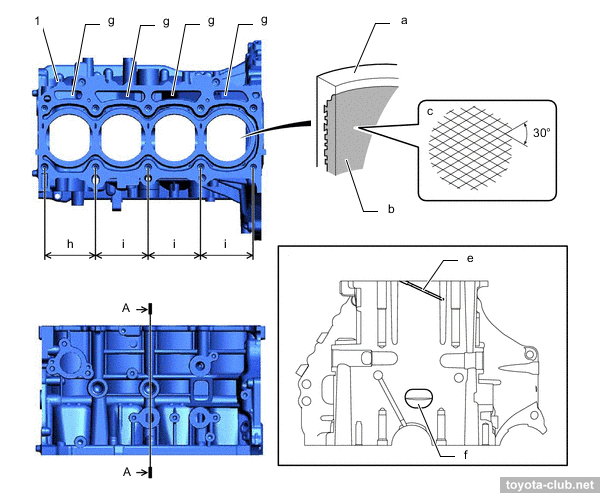

The A25 series engine uses a "long stroke + small bore" design (stroke 103.4mm > bore 87.5mm), and the cylinder block features a composite structure of "aluminum alloy + cast iron liner." This design is a balanced outcome of material performance and manufacturing cost.

1 - Cylinder block. A - Cylinder bore, B - Sleeve, C - Bore cross-hatch, E - Water passage, f - Vent hole, G - Drain plug, H - 94 mm, i - 97 mm

The low density of aluminum alloy (approximately 2.7 g/cm³) effectively reduces engine weight (about 30% lighter compared to an all-cast-iron block), but its thermal conductivity and strength are insufficient to directly withstand the heat load under a high compression ratio (13.0:1).

Therefore, Toyota employs the "cast-in iron sleeve" process, embedding a preheated cast iron sleeve (made of gray cast iron or vermicular graphite cast iron) into the mold during the aluminum alloy block casting process. The flowing liquid aluminum alloy encapsulates the cast iron sleeve, forming a composite structure with an aluminum matrix and an iron core.

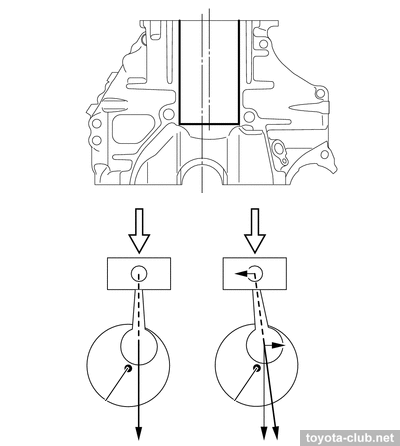

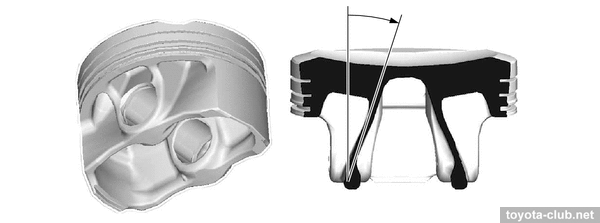

To reduce friction, the crankshaft uses a unique offset design

The crankshaft's "offset layout" (offset by 10mm) is another key process. In traditional engines, the crankpin center coincides with the main journal center, resulting in a relatively large lateral force on the cylinder wall during piston motion (accounting for approximately 15%-20% of the piston force).

The A25 series engine offsets the crankpin by 10mm in the direction of crankshaft rotation, aligning the lateral force direction of the piston during its downward motion with the crankshaft rotation direction, thereby reducing friction loss (friction loss is reduced by about 8%).

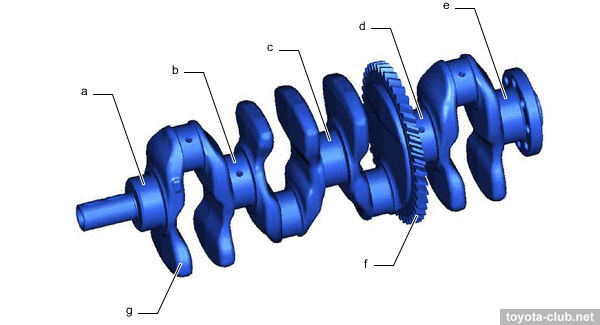

This adjustment requires redesigning the dynamic balance of the crankshaft. Using a laser measuring instrument, the weight distribution on the crank arm is fine-tuned (with a single counterweight block error margin not exceeding 0.1g), ultimately achieving a dynamic balance precision of G1 level for the crankshaft assembly.

A-E-Main Bearing Journal, F-Balance Shaft Drive Gear, G-Counterweight

The Lightweighting Process of Pistons and Connecting Rods

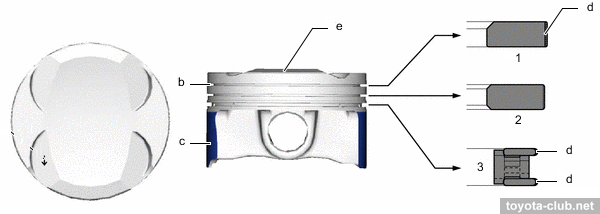

The high compression ratio (13.0:1) and long stroke (103.4mm) design of the A25 series engine place extremely high demands on the strength and lightweighting of pistons and connecting rods. Therefore, the manufacturing process for pistons and connecting rods primarily focuses on "weight reduction + wear resistance."

The tops of traditional engine pistons are designed as flat or shallow concave surfaces. The A25 uses laser etching technology to machine grooves 0.2-0.3mm deep on the top surface of the piston, reducing weight by approximately 10% (about 120g per piston) while ensuring strength. The groove angles on the piston surface align with the swirl direction to guide airflow and form stronger turbulence.

The piston rings feature a narrowed contact width design (e.g., the top compression ring width is reduced to 1.5 mm, compared to a conventional 2.0 mm). When combined with a Diamond-Like Carbon (DLC) coating (applied at a thickness of 2–3 μm), this combination reduces the friction coefficient between the ring/cylinder wall interface from approximately 0.12 to as low as 0.06, thereby decreasing mechanical losses by approximately 15%.

1 - Compression ring 1, 2 - Compression ring 2, 3 - Oil ring. b - Aluminum coating, c - Resin coating, d - DLC coating, e - Combustion bowl

The piston connecting rod is manufactured using powder metallurgy technology, with raw materials comprising iron powder, copper powder, and graphite. It is densified through hot isostatic pressing (HIP), which increases the tensile strength from 800 MPa for traditional forged steel to 1200 MPa.

The big-end bearing (which contacts the crankshaft connecting rod journal) features a thin-wall design, reducing thickness from 5 mm to 3 mm. Its surface undergoes induction hardening, and micro-textures are laser-etched onto it to store lubricant and reduce friction.

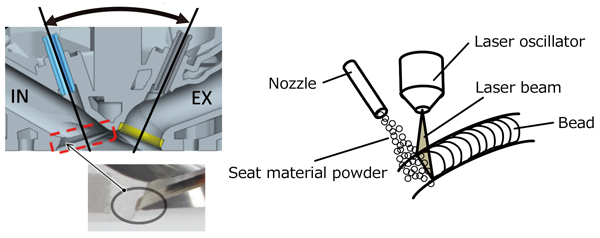

Laser Cladding Technology in A25 Series Engine Cylinder Heads

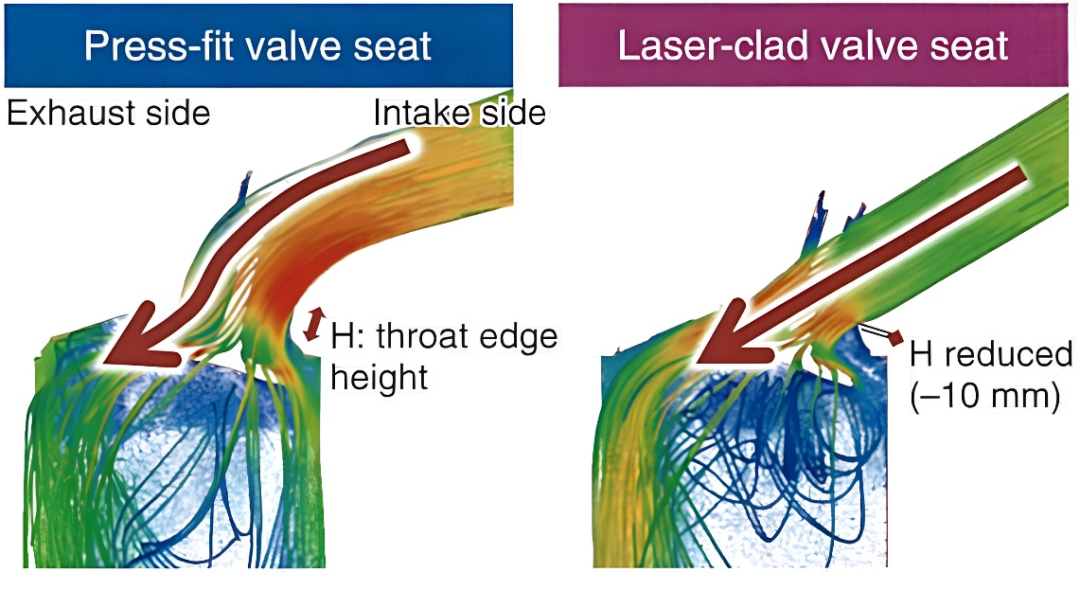

The combustion efficiency breakthrough in the A25 series engine depends on high-velocity combustion technology. A key method to achieve this is by increasing the included angle between the intake and exhaust ports to 41 degrees, which enables the airflow to enter the cylinder at a lower angle and generate a more intense in-cylinder tumble flow.

In traditional engines, the included angle between the intake and exhaust ports is constrained by the strength of the cylinder head material. Excessively large port angles can result in thinner valve seat inserts, compromising their structural integrity.

In contrast, the A25 series engine utilizes laser cladding technology for its valve seats: a layer of copper-chromium alloy (approximately 0.3 mm thick) is fused onto the valve seat insert surface. This clad layer exhibits a hardness (HV 800-1000) significantly higher than that of the aluminum alloy cylinder head (HV 100-150). Furthermore, the laser process itself achieves surface densification, which helps prevent wear under high-temperature operation.

This process extends the service life of the intake valve seat to over 300,000 kilometers (compared to approximately 200,000 kilometers for traditional press-fitted seats). However, this process is also very costly. It is reported that the cost of this process can account for half of the cylinder head production cost.

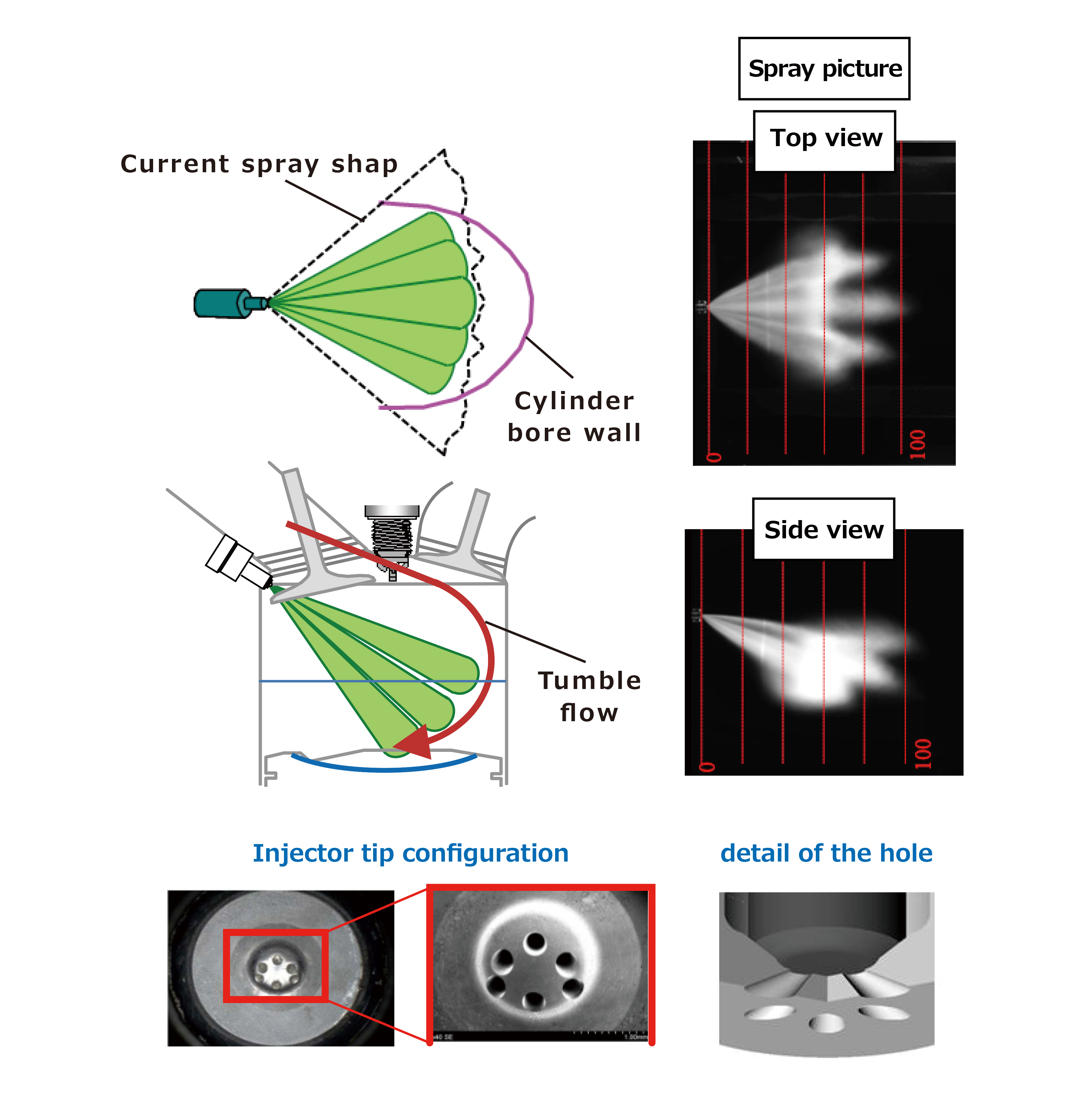

Dual Injection System of the A25 Series Engine

The A25 retains both the port fuel injection (PFI) and direct injection (DI) systems.

The port fuel injector is installed in the intake manifold and must match the shape of the intake port with precision (spray angle error ≤1°) to ensure a fuel atomization particle size of ≤20μm. The direct injector is integrated into the cylinder head, using a "multi-hole nozzle" design (6-8 holes with apertures of 0.15-0.2mm). Laser drilling technology ensures flow consistency among the holes (deviation <2%).

The coordinated control of the two systems demands that the ECU (Engine Control Unit) perform real-time switching. The calibration of this switching logic must encompass ambient temperatures from -30 °C to 50 °C to guarantee optimal combustion across all operating conditions, such as cold starts, low-load, and high-load scenarios.

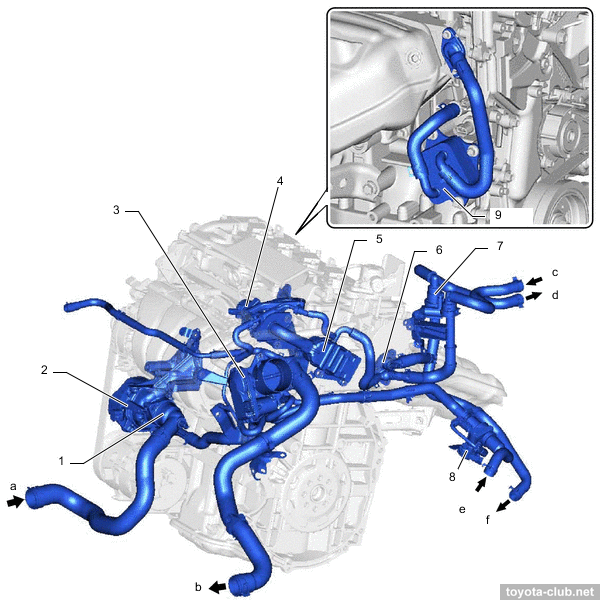

Thermal Management System in the A25 Series Engine

The thermal management system is considered a benchmark design. Its essence lies in the synergistic operation of an electric water pump, a variable thermostat, and a water-cooled EGR cooler, enabling rapid warm-up and precise temperature control.

The electric water pump's manufacturing process represents a significant advancement over traditional mechanical water pumps

Traditional pumps are driven by the crankshaft belt, with their speed linked to engine speed (e.g., at 2000 rpm, the water pump rotates at approximately 4000 rpm). This results in low warm-up efficiency during a cold start, requiring 8-10 minutes to reach 80 °C.

The electric water pump in the A25 series engine is directly controlled by the ECU (12V voltage, approximately 150W power), enabling speed adjustment across a 0-100% range.

Its impeller is manufactured via injection molding using engineering plastic (PA66+GF30), with its blade geometry optimized through 3D scanning to enhance hydraulic efficiency. The bearings incorporate ceramic balls paired with an engineering plastic cage (reducing the friction coefficient by approximately 40%), contributing to a lifespan exceeding 200,000 kilometers.

The ball-valve design employed in the variable thermostat represents another key innovation

Traditional thermostats use wax-based thermal elements to control valve opening, resulting in slow response times (taking 5-8 minutes to reach 80 °C from a cold start).

The thermostat in the A25 series engine integrates an electronically controlled ball valve (approximately 20 mm in diameter) driven by a stepper motor, capable of increasing coolant flow from 10 L/min to 40 L/min within 20 seconds.

The ball valve surface is coated with a DLC (Diamond-Like Carbon) layer (approximately 5 μm thick), which reduces the friction coefficient to as low as 0.05 (compared to approximately 0.15 for traditional metal valves), thereby effectively preventing seizing issues during long-term operation.

Manufacturing Process of the Water-Cooled EGR Cooler

The EGR cooler must cool high-temperature exhaust gas (approximately 600 °C) to below 150 °C while resisting corrosion from the coolant.

Toyota employs a tube-fin structure, comprising a heat exchanger core with 30 stainless steel tubes (each with an outer diameter of 8 mm), which is externally fitted with aluminum fins (1.5 mm thick, featuring stamped louvered patterns on the surface).

The assembly is joined via vacuum brazing, a process during which the components are heated to 600 °C in a vacuum chamber to liquefy the brazing filler metal, allowing it to flow into and seal the interfaces, which ensures both high heat transfer efficiency and structural integrity.

Defects in the A25 Series Engine

Despite the A25's manufacturing processes being among the most advanced in the industry, its complex systems have revealed some durability issues.

For instance, the corrosion issue in the water-cooled EGR cooler stems from an electrochemical reaction between the stainless steel tubes and the coolant. Toyota initially used 316L stainless steel, which offers pitting resistance, but localized corrosion still occurred in high-temperature (above 100 °C) and high-chloride ion environments (resulting from decomposed coolant additives).

Subsequent improved versions substituted 316L with nickel-based alloys (e.g., Hastelloy C-276) and introduced corrosion inhibitors into the coolant, thereby reducing the corrosion rate to less than 0.01 mm/year.

Additionally, early versions of the A25 series engine used PA66 (glass transition temperature 150 °C). Under long-term operation in the high-temperature engine bay (exceeding 120 °C), the impeller was prone to creep deformation (elongation ≥ 0.5%).

The improved version uses PPS (polyphenylene sulfide, glass transition temperature 280 °C) reinforced with 30% glass fiber, reducing the creep deformation rate to below 0.1% and extending the service life to 300,000 kilometers.

The process of resolving these issues essentially involves the integration of manufacturing processes and usage scenarios. The manufacturing process of the A25 series engine is the ultimate extension of Toyota's "lean production" philosophy in the field of internal combustion engines.

In the future, as electrification accelerates, the reliability of the A25 series engine will be further optimized. However, there is no doubt that the A25 series engine has already become an important example of internal combustion engine technology.

If any infringement occurs, please contact us for deletion

Trending News

Perodua Myvi and Bezza may undergo major upgrades in 2026

After the update, the Bezza will no longer be just a low-cost alternative but a core model in the Perodua system with greater market competitiveness and brand premium potential. The upgrade of the Myvi is not to be unconventional but to strengthen the brand and market, ensuring that the Myvi continues to maintain its irreplaceable position in the new round of product competition.

Perodua Traz VS Ativa, which one is more worth buying?

Traz, as a newly launched mid-sized SUV, offers more spacious room and mainstream power compared to small SUVs, but its pricing appears slightly higher than that of Ativa. Ativa, on the other hand, is Perodua's long-time best-selling small SUV with more affordable pricing and a balanced combination of power and tech features.

Will the Toyota Yaris Cross come to Malaysia? If it comes, how much will it sell for?

The launch of Perodua Traz indicates that the market size of small SUVs in Malaysia has been expanding in recent years. However, the question naturally shifts back to Toyota. As a brand with the most comprehensive product line and a strong foundation in both the SUV and hybrid sectors, will Toyota choose the Yaris Cross to participate in this small SUV competition?

Perodua Traz VS Toyota Yaris Cross, where does the Traz fall short?

Before the official launch of the Perodua Traz, market expectations were actually very high because it shares the same DNGA platform as the Toyota Yaris Cross. However, sharing the same platform does not equate to the same experience, and the Traz's final performance has indeed been disappointing. Perhaps it is precisely because of the delayed launch that it has almost no competitiveness in the current competitive environment.

Perodua Traz 2025:Spec, Price and Features

Perodua Traz has been officially launched in Malaysia. It is a B-segment five-seater SUV built on the DNGA platform. Compared to the Yaris Cross, which emphasizes brand and quality, the Traz comes with a localized rate of about 95%, offering a more friendly price and practical features.

Popular Cars

Model Year

Car Compare

Car Photo