Toyota announced that the earliest mass production of solid-state batteries will be in 2027, and has currently developed highly durable cathode materials.

MichaelOct 13, 2025, 03:22 PM

MichaelOct 13, 2025, 03:22 PM

[PCauto] Toyota and Sumitomo Metal Mining jointly announced on October 8, 2025, that they have reached a collaborative development agreement for the mass production of solid-state battery cathode materials, aiming to launch pure electric vehicle models equipped with solid-state batteries between 2027 and 2028.

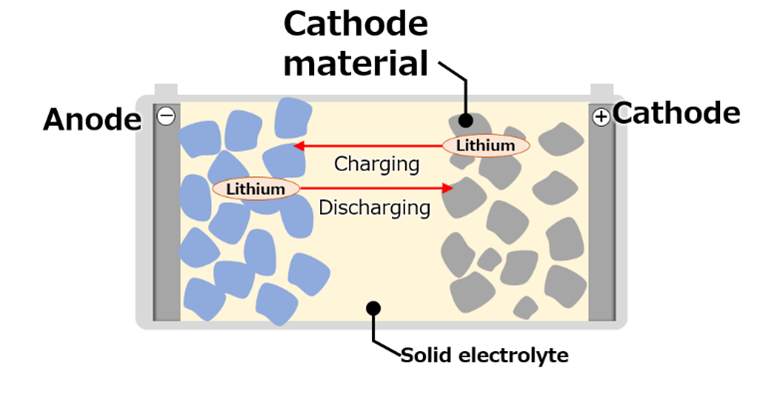

Solid-state batteries offer the advantages of high energy density and improved safety

Compared to liquid lithium batteries, which have dominated the electric vehicle market since the General Motors EV1 in 1996, solid-state batteries can achieve a 30% to 50% improvement in energy density, directly translating into longer driving ranges.

In terms of technical specifications, Toyota's solid-state batteries aim to achieve an energy density of 450-500Wh/kg, approximately twice that of current liquid lithium batteries.

The target driving range will exceed 800 kilometers, while charging times are expected to be reduced to under 10 minutes for replenishing 10% to 80% of the battery capacity, providing an experience comparable to refueling traditional gasoline vehicles.

The battery cycle life is expected to exceed 2,000 cycles, significantly higher than the 1,000-cycle standard of traditional lithium batteries, meaning the battery pack may not require replacement throughout the entire vehicle lifecycle.

The compact design of the battery pack allows the height to be reduced to 120mm, compared to the 150mm battery pack of the existing bZ4X model, creating conditions for a low center of gravity design and aerodynamic optimization of the vehicle.

These technological advancements not only enhance vehicle performance but also provide designers with greater flexibility in interior space layout.

Toyota and Sumitomo Metal Mining to Jointly Promote Mass Production of Solid-State Batteries by 2027

Toyota's collaboration with Sumitomo Metal Mining began in 2021, focusing on addressing the degradation of cathode materials in solid-state batteries during repeated charge-discharge cycles.

Sumitomo Metal Mining, leveraging its proprietary powder synthesis technology, has developed "high-durability cathode materials" suitable for solid-state batteries.

With over 20 years of experience in supplying cathode materials for electric vehicles, the company’s collaboration with Toyota will accelerate the mass production process of the new materials.

Additionally, Toyota has partnered with Idemitsu Kosan, which is building a lithium sulfide production facility with an annual capacity of 1,000 tons.

Lithium sulfide, as a key solid electrolyte material for solid-state batteries, is planned to begin production in 2027, providing core material support for large-scale battery manufacturing.

These collaborations are an important part of Japan's strategy to establish a self-sufficient supply chain for advanced battery materials, aiming to reduce reliance on suppliers from China and South Korea.

Global Automakers Are Intensively Advancing Solid-State Battery Development

Japanese companies and the government have made substantial investments in all-solid-state battery R&D, with government support alone reaching billions of dollars.

Globally, BMW, Honda, Mercedes-Benz, Stellantis, Tesla, and other manufacturers are actively advancing solid-state battery development, but Toyota is among the leading automakers that have set clear production timelines for solid-state batteries.

Chinese manufacturers such as CATL and BYDCATL plan to mass-produce semi-solid-state batteries by 2027 with an energy density target of 500Wh/kg.

Meanwhile, Western companies like QuantumScape and Solid Power are focusing on oxide electrolyte routes.

Despite the bright prospects for all-solid-state batteries, mass production still faces many challenges. Technical issues such as interface contact resistance and lithium dendrite suppression have not been fully resolved, and the current cost of sulfide electrolytes is as high as $300/kg, which is more than 50 times that of liquid electrolytes.

If any infringement occurs, please contact us for deletion

Trending News

Perodua Myvi and Bezza may undergo major upgrades in 2026

After the update, the Bezza will no longer be just a low-cost alternative but a core model in the Perodua system with greater market competitiveness and brand premium potential. The upgrade of the Myvi is not to be unconventional but to strengthen the brand and market, ensuring that the Myvi continues to maintain its irreplaceable position in the new round of product competition.

Perodua Traz VS Ativa, which one is more worth buying?

Traz, as a newly launched mid-sized SUV, offers more spacious room and mainstream power compared to small SUVs, but its pricing appears slightly higher than that of Ativa. Ativa, on the other hand, is Perodua's long-time best-selling small SUV with more affordable pricing and a balanced combination of power and tech features.

2026 Honda Jazz minor facelift exposed in the Chinese market, featuring a new front-end design

The fourth generation Honda Jazz (known as Fit in some markets) has maintained stable global sales since its launch in 2019, but its performance in the Chinese market has been less optimistic. Now, the Chinese market is about to welcome its second facelift. The new model has undergone significant upgrades in exterior and interior design, while retaining the current 1.5L naturally aspirated engine and CVT transmission system.

Proton e.MAS 7 OTA upgrades to Flyme Auto 1.2.0, completing the Android Auto interconnection ecosystem

Proton has officially released the Flyme Auto 1.2.0 version OTA update for e.MAS 7 users. The core of this upgrade is the addition of support for Android Auto, offering both wired and wireless connection options. Combined with the previously integrated Apple CarPlay feature, it achieves full coverage of the two major smartphone ecosystems, Android and Apple. This marks a step towards perfecting the smart cockpit experience of the e.MAS 7 all-electric SUV and is also a key milestone in Proton's phased software iteration plan.

2026 New Proton S70 Upgrades from Three-cylinder to Four-cylinder, Significantly More Powerful!

Proton's 2026 S70 to be launched before Lunar New Year, with a key upgrade to a 1.5-liter four-cylinder turbocharged engine replacing the three-cylinder model, improving power smoothness, maintaining spaciousness, with the infotainment system and driver assistance possibly adapted to local road conditions, offering practical improvements tailored to the needs of Malaysian and Thai family users, aiding car purchase decisions.

Popular Cars

Model Year

Car Compare

Car Photo