Ferrari unveils the chassis and core components of its first all-electric model, Elettrica

LienOct 10, 2025, 11:36 AM

LienOct 10, 2025, 11:36 AM

[PCauto] At the Capital Markets Day 2025 event held in Maranello, Italy, Ferrari unveiled the core secrets of its first all - electric model, the Elettrica: not the complete body, rather than the chassis, battery, motor, and control system that have been developed over five years.

This launch event was more like a technical defense. With 210 battery cells, a 9 kg front axle inverter, and accelerometers capable of capturing motor vibrations, Ferrari proved to the outside world that even fully electric models can retain the core driving pleasure of the Prancing Horse.

From hybrid to all-electric, Ferrari has accumulated a decade of technical expertise

The arrival of the Elettrica is not by chance. Ferrari's journey towards electrification began in 2009, when F1 cars first adopted the KERS kinetic energy recovery system. This was followed by the 2010 599 HY-KERS prototype, the 2013 LaFerrari plug-in hypercar, and later plug-in models such as the SF90 Stradale and 296 GTB. Over more than a decade, Ferrari has been amassing its core electrification technologies.

As CEO Benedetto Vigna stated: "We will not go electric just for the sake of being electric. Only when the technology ensures that the vehicle maintains Ferrari's performance and driving pleasure will we launch an all-electric model."

Elettrica is a pure electric platform vehicle designed entirely in-house, from the chassis to the motor. The brand positions it as a "forever EV," a long-lasting and easy-to-maintain electric sports car. Even the battery modules can be replaced individually without damaging the vehicle structure.

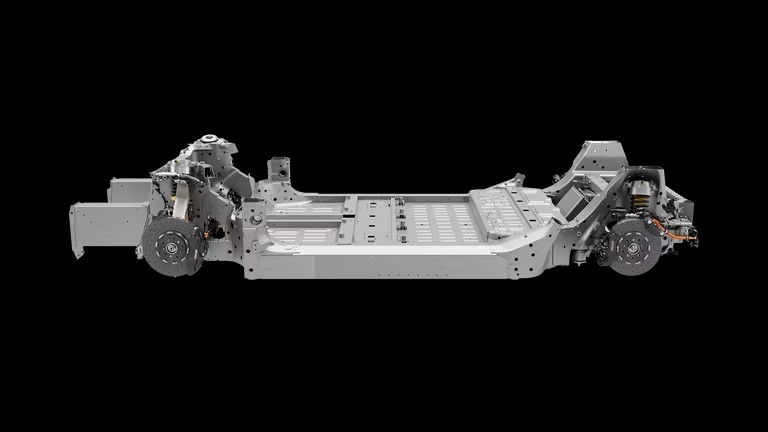

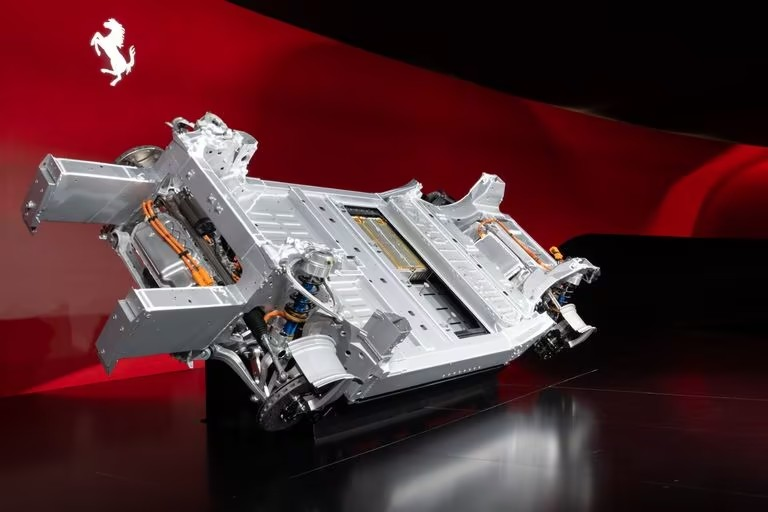

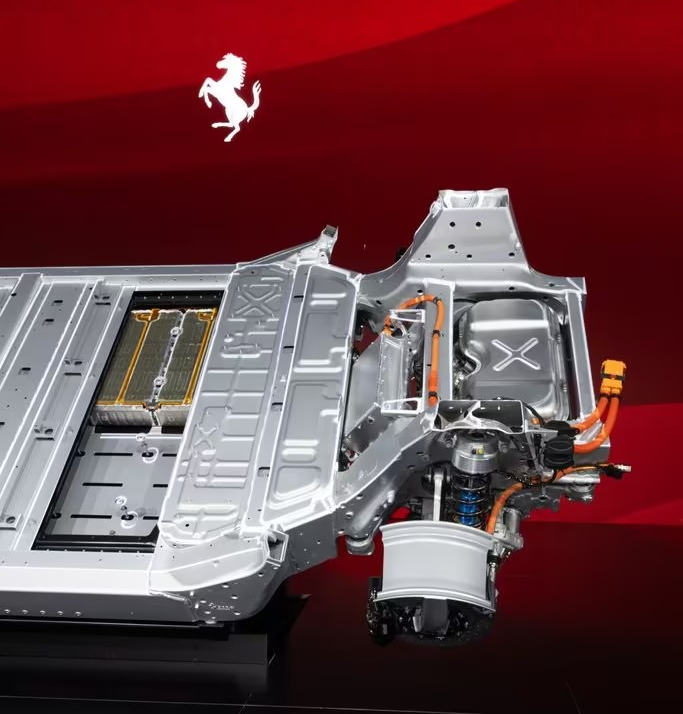

The chassis adopts a lightweight design while taking safety into account

Elettrica's chassis features a short - wheelbase layout, with the driver's seat positioned closer to the front axle. This design retains the comfort of a GT vehicle while providing pure dynamic feedback.

To address collision safety issues in electric vehicles, the front shock towers are designed as energy - absorbing structures. The positions of the front motor and inverter are deliberately positioned to disperse the impact before it reaches the chassis joints. This means that even in the event of a collision, the energy will be absorbed by the vehicle structure rather than transmitted to the passenger cabin. The battery is another core element of the chassis. It is fully integrated beneath the floor, with 85% of the module weight distributed under the floor and the remaining 15% beneath the rear seats. This design lowers the vehicle's center of gravity by 80 mm compared to similar internal combustion engine vehicles, achieving a perfect 47:53 front-to-rear weight distribution.

The battery is another core element of the chassis. It is fully integrated beneath the floor, with 85% of the module weight distributed under the floor and the remaining 15% beneath the rear seats. This design lowers the vehicle's center of gravity by 80 mm compared to similar internal combustion engine vehicles, achieving a perfect 47:53 front-to-rear weight distribution.

The battery pack itself also functions as a structural component: the cells are concentrated in the center of the module, surrounded by an aluminum shell creating an energy - absorbing zone; the cooling plate is integrated at the bottom of the battery. This design not only lowers the center of gravity but also absorbs impact during collisions.

Ferrari states that this design ensures the battery pack meets the brand's impact resistance standards while maintaining lightweight construction — the entire chassis and battery system are only approximately 200 kg heavier than a traditional fuel vehicle.

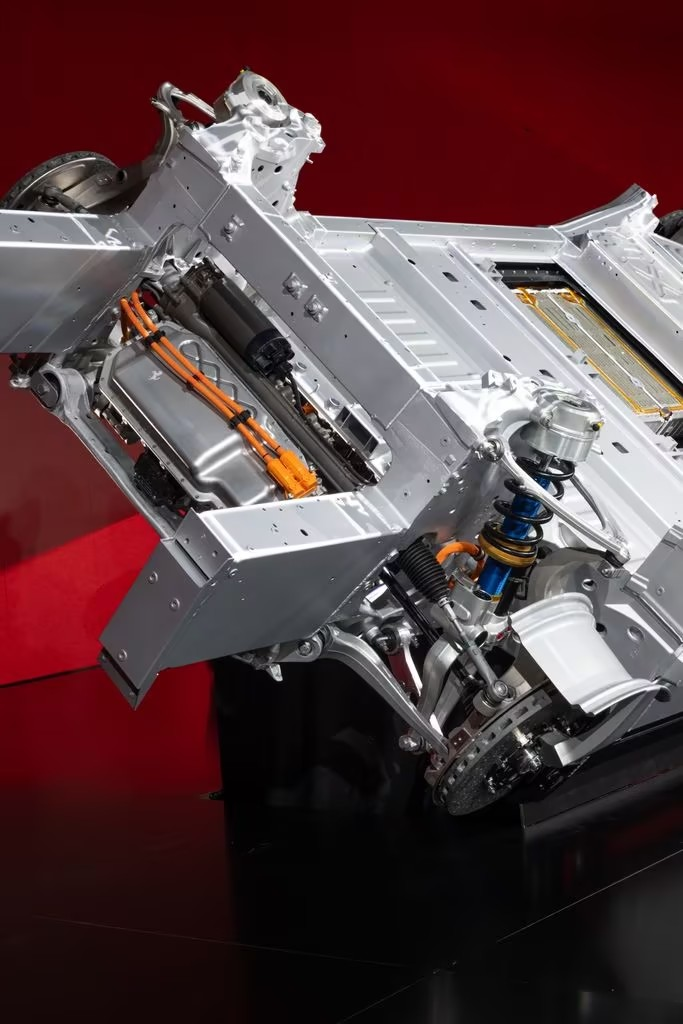

Motors and Battery Employ Proprietary Core Technologies

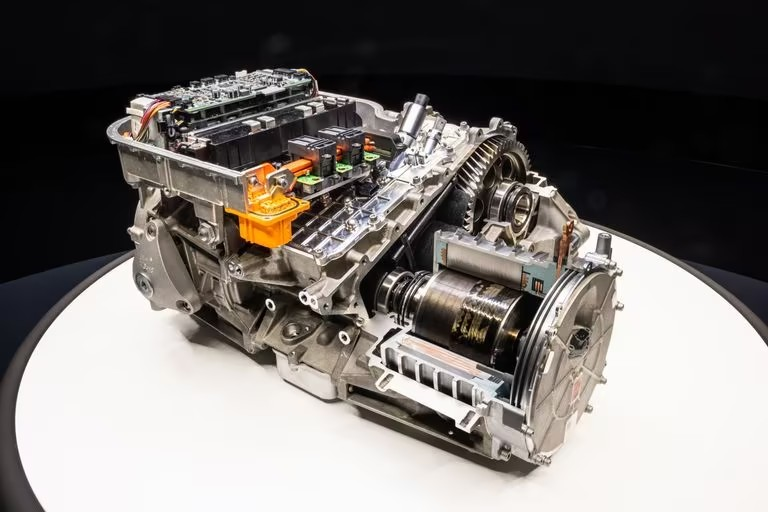

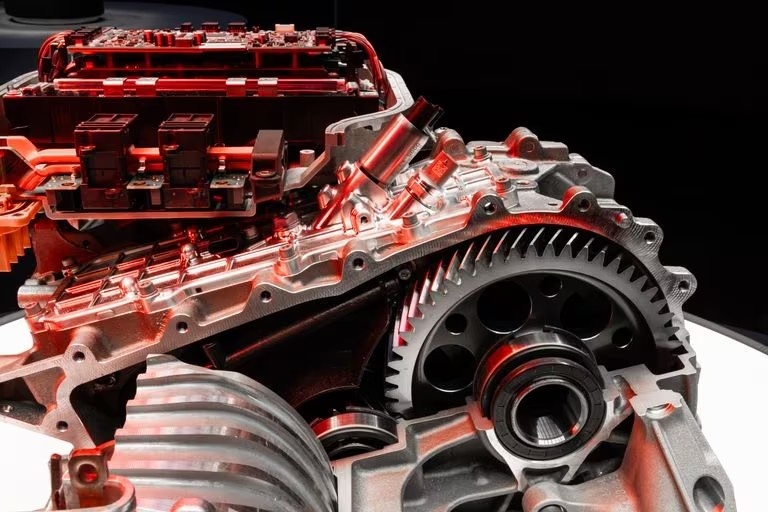

The Elettrica's power comes from four independently developed permanent magnet synchronous motors, with two on each axle, forming a dual e-axle system.

The front axle motors have a combined power output of 210 kW and can deliver 3500 Nm; the rear axle provides 620 kW, and in "Performance Launch" mode, the rear axle can unleash 8000 Nm. The total peak power of the entire powertrain exceeds 1000 hp.

This level of performance is not achieved by simply stacking motor windings but originates from the motor's extreme design:

• Rotor and stator: The rotor uses a racing-grade Halbach array, with surface-segmented permanent magnets arranged directionally to concentrate the magnetic field toward the stator, enhancing torque density; the stator is made of 0.2 mm ultra-thin silicon steel sheets bonded together, reducing eddy current losses.

• Windings and cooling: The stator windings use Litz wire to reduce skin effect losses at high frequencies; the motor is filled with high thermal conductivity resin via vacuum injection, which has a thermal conductivity 40 times that of air, ensuring temperature control during high-speed operation.

• Carbon sleeve: The carbon fiber sleeve inside the rotor is only 1.6 mm thick, yet it can secure the high-speed rotating magnets—in conditions of 30,000 rpm, a single magnet generates 390 bar of centrifugal force, and the carbon sleeve solves this problem with minimal weight.

Thanks to these technologies, the power density of Elettrica's front axle reaches 3.23 kW/kg with a peak efficiency of 93%, while the rear axle achieves a power density of 4.8 kW/kg with the same efficiency level. The front inverter is fully integrated into the axle, weighing just 9 kilograms.

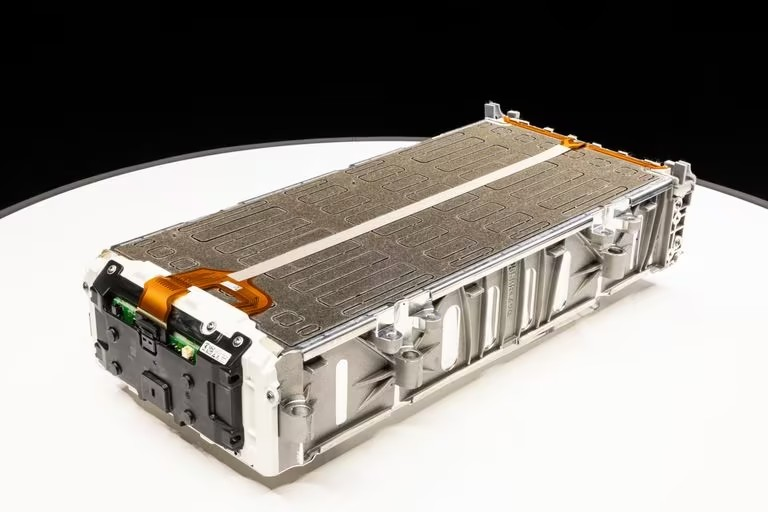

Regarding the battery, Elettrica uses SK Innovation's NMC pouch cells. A total of 210 cells form 15 modules, with a total capacity of 122 kWh and an energy density of 195 Wh/kg (cell density of 305 Wh/kg).

The battery supports 350 kW fast charging, providing approximately 100 km of range in 10 minutes.

Ferrari has independently designed the Battery Management System (BMS) and cooling system: cooling circuits are integrated within the battery using a "return-supply" unified design to ensure consistent temperature across all cells and prolong lifespan.

Transferring Ferrari's suspension tuning expertise from fuel vehicles to electric platforms

Electrification does not mean sacrificing handling. Elettrica inherits Ferrari's third-generation 48V active suspension while optimizing it for electric-specific characteristics:

• Adjusted thread pitch: The recirculating ball screw inside the shock absorbers has its thread pitch increased by 20%, reducing inertial forces transmitted from road impacts to the body.

• Independent rear subframe: The rear axle is equipped with Ferrari's first independent subframe, utilizing hollow casting technology to reduce weight while isolating NVH from the motor. The active suspension inverter is integrated into the subframe, leveraging its mass to absorb vibrations without the need for additional passive components.

• Full-dimensional control: The suspension, steering, and torque vectoring system of all four wheels are managed by a single control unit, with a response time of just 5 milliseconds. The rear-wheel steering system can pivot by 2.15 degrees, combined with four-wheel torque distribution, giving this nearly 2.3-ton electric vehicle agility close to that of a fuel-powered supercar.

Elettrica can provide drivers with a unique electric motor sound

For the sound of pure electric vehicles, Ferrari offers a different answer: instead of simulating internal combustion engines or using digital synthesis, it chooses to “amplify the real motor sound.”

The accelerometer on the rear axle captures the vibrations of the motor and transmits them to the cockpit through an amplifier, similar to the principle of a guitar pickup. The sound is not always present: it remains quiet during daily driving but activates to provide dynamic feedback when the driver presses the accelerator pedal or uses the manual shift paddles.

On the interaction front, the two controllers on the steering wheel carry on Ferrari's tradition: the right - side Manettino adjusts the vehicle's dynamics (ranging from the Ice mode featuring stable four - wheel drive to the ESC - Off mode with pure rear - wheel drive); the left - side eManettino manages energy distribution—allowing the selection of rear - wheel drive only, four - wheel drive, or performance mode, with variations in power output and driving configurations under different modes.

In addition, the “Torque Shift Engagement” function employs the shift paddles to implement five levels of torque increment, mimicking the gear - shifting sensation of a conventional transmission, offering a more ritualistic acceleration experience.

Elettrica will unveil its full appearance in spring 2026

Currently, the design of Elettrica has been completed, and the prototype vehicle is currently undergoing on - road testing. Ferrari has confirmed that the model will be a four - door sedan, not a supercar, and it was designed in partnership with the LoveFrom studio (founded by Jony Ive and Marc Newson).

The production version will make its global debut in spring 2026. Regarding the price, it will be comparable to the gasoline - powered version of the Purosangue.

If any infringement occurs, please contact us for deletion

Trending News

Proton e.MAS 7 OTA upgrades to Flyme Auto 1.2.0, completing the Android Auto interconnection ecosystem

Proton has officially released the Flyme Auto 1.2.0 version OTA update for e.MAS 7 users. The core of this upgrade is the addition of support for Android Auto, offering both wired and wireless connection options. Combined with the previously integrated Apple CarPlay feature, it achieves full coverage of the two major smartphone ecosystems, Android and Apple. This marks a step towards perfecting the smart cockpit experience of the e.MAS 7 all-electric SUV and is also a key milestone in Proton's phased software iteration plan.

2026 New Proton S70 Upgrades from Three-cylinder to Four-cylinder, Significantly More Powerful!

Proton's 2026 S70 to be launched before Lunar New Year, with a key upgrade to a 1.5-liter four-cylinder turbocharged engine replacing the three-cylinder model, improving power smoothness, maintaining spaciousness, with the infotainment system and driver assistance possibly adapted to local road conditions, offering practical improvements tailored to the needs of Malaysian and Thai family users, aiding car purchase decisions.

Perodua Ativa Hybrid may be launched, a fuel-efficient small car that doesn't require charging

According to reports, the Perodua Ativa may be preparing to launch a hybrid version. The new car is expected to use an Extended Range Electric Vehicle (EREV) system for two main reasons: first, better fuel efficiency; second, to make users barely notice any difference compared to conventional fuel vehicles. It is clear that the automaker intends to use a very practical approach to gradually lead consumers into the era of electric vehicles.

Toyota Estima to return in 2026?

Since it was discontinued in 2019, news about the return of the Toyota Estima to the market has never stopped. Although Toyota has not yet released any official announcements regarding mass-production vehicles, the related information does not come from scattered rumors but originates from continuous revelations by Japanese automotive media.

In 2026, Should I Buy a Proton X50 or a Perodua Traz? Can the RM 6,000 Rebate Offset the Traz's Space Advantage?

Recently, one of the most frequently asked questions in the Malaysian market is: So, should you go for the Proton X50, which offers stronger performance and a greater sense of technology, or the Perodua Traz, which provides more space and is more budget-friendly? Especially considering the X50 has discounts of up to around RM 6,000, how significant is the price difference left to weigh? This article provides an objective analysis from the perspective of daily usage.

Popular Cars

Model Year

Car Compare

Car Photo